Instructions Manual

-

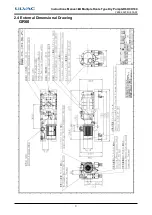

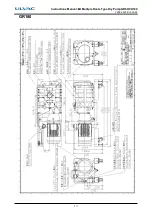

Multiple Roots Type Dry Pump GR60/90/180

YK09-0023-DI-003-02

22

(1) Before connecting electric wires, be sure to turn off the power

switch.

Never do this work with voltage applied.

(2) Securely connect to ground. There is a risk of an electric shock in

the event of a breakdown or leakage of electricity. The earth terminal

on the motor is the screw indicated by the "Earth Mark" in the

terminal box. The wire diameters of the power cord for supplying

power to the motor and the power cord connected to ground shall

be the same.

(3) Do not use at a voltage other than the motor's rated voltage.

Otherwise overload protective equipment does not work correctly,

which may result in a motor burnout or fire.

(1) Be sure to install overload protective equipment suitable for the

motor capacity. To prevent a motor burnout, install overload

protective equipment in the electric connections. If overload

protective equipment is not installed or it is installed but not

suitable for the motor capacity, a motor burnout or fire may occur.

We recommend installing protective equipment (such as an earth

leakage breaker) in addition to overload protective equipment.

(2) Do correct wiring work according to the electrical equipment

technical standards and indoor wiring regulations. Wrong wiring

work may trigger fire.

(3) Use an appropriate electric insulated wire for the power cord which

can tolerate the above rated current value.

(1) The motor's rated current value depends on the motor

manufacturer. Use overload protective equipment that works at the

rated current of the motor you use.

(2) Make the connections for full-voltage start. Otherwise it may be

difficult to start with a star/delta connection.

To prevent a motor burnout due to overcurrent, install overload

protective equipment in the electric connections. If overload protective

equipment is not installed or it is installed but not suitable for the motor

capacity, a motor burnout or fire may occur.

WARNING

WARNING

WARNING

WARNING