12

2) Replacing DA-121D series and DA-241S series Diaphragms

It is recommended that both diaphragms be replaced simultaneously.

Use tools 1, 2, 4, 5, 6 and 7 listed above. (Note: Always wear gloves.)

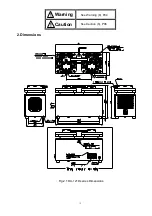

(1) Remove the eight M8×25 hex socket head screws shown in Photo 1.

(2) Lift the edge of the stage 1 diaphragm shown in Photo 2, turn it anti-clockwise, and

remove it.

Note: The diaphragm is more easily removed by two persons.

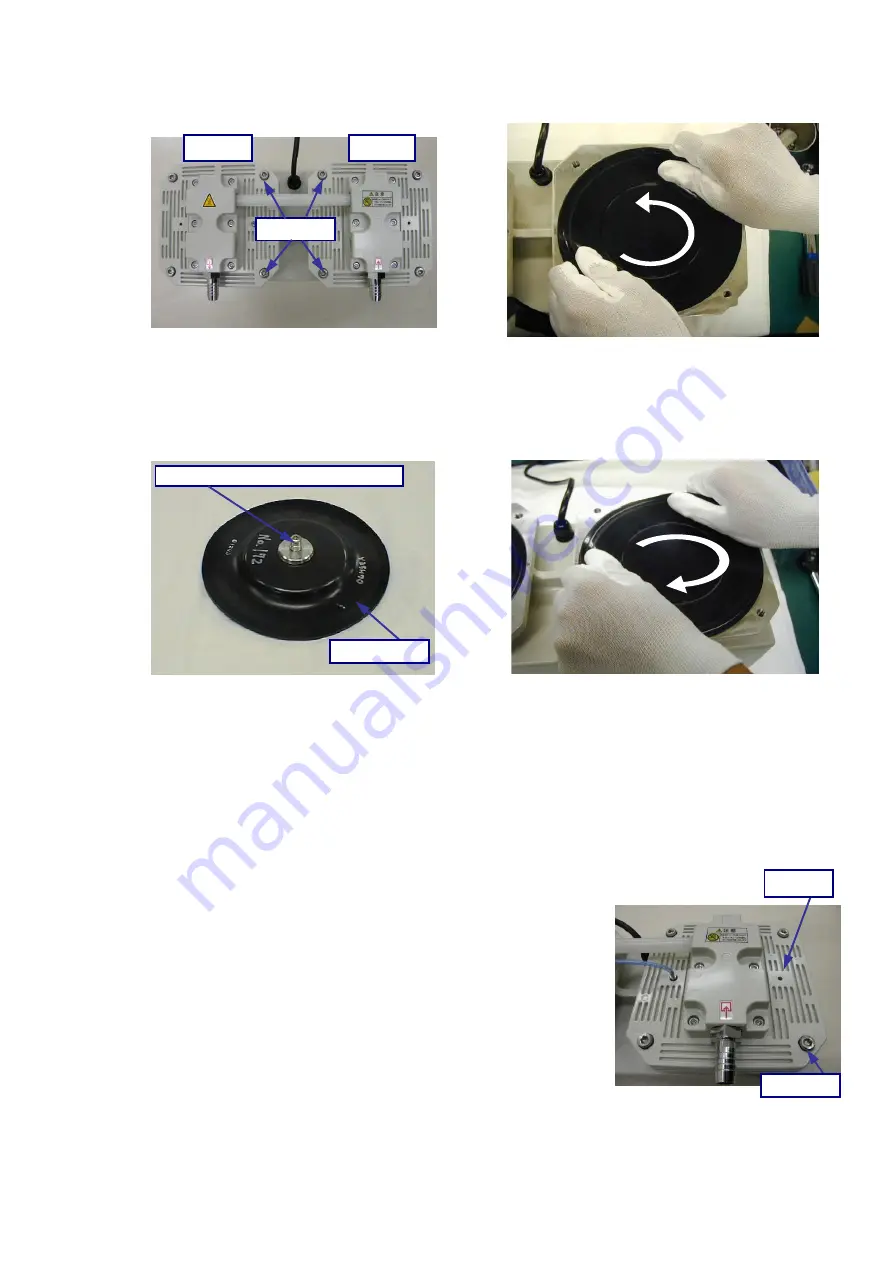

(3) Apply a small amount of vacuum grease to the hex socket head screw (M10×25, Photo 3)

at the rear of the new diaphragm to prevent scoring.

(4) Turn the diaphragm in the clockwise direction as shown in Photo 4 as far as it will go, and

tighten it a further 5

~

10°. Take care not to overtighten the diaphragm.

(5) Replace the stage 2 diaphragm as described in (2), (3) and (4).

(6) Using the torque wrench, tighten diagonally opposite pairs of the four stage 1 pump head

hex socket head screws (M8×25) equally to 18 N

・

m as shown in Photo 5.

(7) Fit the connecting pipe to the stage 1 side.

Note: Always fit the connecting piping from

the stage 1 side, and push it in as far

as possible.

(8) Using the torque wrench, tighten diagonally

opposite pairs of the four stage 2 pump head

hex socket head screws (M8×25) equally to

18 N

・

m.

(9) Close the inlet, set the switch to ON (ie to I),

and 2 hours later, use the torque wrench to

tighten diagonally opposite pairs of the eight

hex socket head screws (M8×25) equally to

20 N

・

m.

Photo 2

Photo 1

Stage 2

Stage 1

M8×25

Photo 4

Photo 3

Diaphragm

Hex socket head screw (M10×25)

1枚

Photo 5

M8×25

Stage 1