13

It is forbidden to carry out any kind of work

on the pressure vessel and piping, this

covering welding and constructional

changes, etc. Breaking this rule means

extreme danger for you and your col-

leagues.

Attention! If the pressure vessel is operated

at temperatures over 60°C, suitable protec-

tion to prevent contact must be provided.

A pressure gauge that shows the opera-

tional pressure must be installed in the unit.

Depressurize the system before carrying

out any work on the pressure vessel.

Clean the piping before carrying out the

installation work.

The unit must be installed vertically in the

piping.

Ensure that the pressure vessel is installed

without any stresses.

Disconnect the power supply when carrying

out electrical work.

The equipment may only be used for its

intended purpose. The equipment has been

built exclusively:

For operating media of

group 2

as per

Pressure Equipment Directive 97/23/EC.

To separate out microbiological organisms

so as to produce 100% sterile compressed

air.

For the filtration of saturated steam.

Any other form of use or one going beyond

this shall be considered as inappropriate.

We shall have no liability whatsoever for any

damage incurred as a result!

PICTURES 1 - 10 (single)

PICTURES 1 - 10 (multiple)

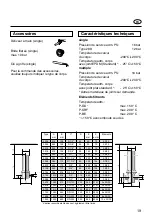

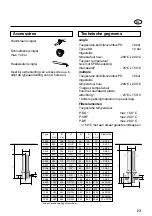

Before initial commissioning

The filter elements are not already installed

in the state in which they are supplied!

All the screwed connections of the pressure

vessel must be done up to the required and

max. permissible tightening torques for the

screws and bolts.

Make a visual check! There must be no

external damage visible.

Make a check for leaks!

Initial commissioning

Slowly

apply pressure to the system by

first opening the downstream valve

(9)

.

Notes on starting up

Appropriate use

GB

Summary of Contents for P-EG

Page 1: ......

Page 2: ...DE GB FR NL IT ES PT DK SE FI GR ...

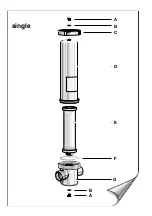

Page 4: ...A B C D E F G B A single ...

Page 5: ...A B B A D E G multiple H O O N I J M L K ...

Page 6: ...2 0 bar 3 4 5 1 2 6 7 8 1 2 11 0 10 bar 12 13 14 15 single 1 2 16 1 1 2 9 10 ...

Page 7: ...2 0 bar 3 4 5 1 2 6 2 1 9 10 7 8 2 1 11 0 10 bar 12 13 14 15 16 2 1 17 multiple 1 ...

Page 48: ...48 A B C D E F G H I J K L M N O GR ...

Page 49: ...49 1 10 single 1 10 multiple 9 GR ...

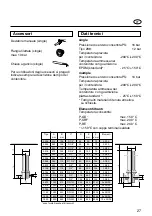

Page 50: ...50 11 16 single 11 17 multiple P GS P SRF P BE 14 single DIN 11851 multiple DIN 2690 GR ...

Page 52: ......