12

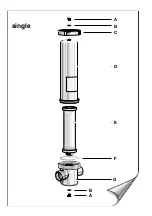

A

Plug

B

Gasket

C

Screw locking ring

D

Upper housing bowl

E

Filter element(s)

F

Sealing ring

G

Lower housing bowl

H

Hexagonal screw

I

Tension nut

J

Spring

K

Bracket plate

L

Tie rod

M

Gasket

N

Hexagonal nut

O

Washer

The relevant safety at work and accident

prevention regulations, plus the operating

instructions, shall apply for operation of the

pressure vessel. The pressure vessel has

been constructed in accordance with the

generally recognized rules of engineering.

It complies with the requirements of directive

97/23/EC concerning pressure vessels.

The relevant applicable national regulations in

force at the place of installation concerning

the operation and routine testing of pressure

vessels must be complied with.

You as operator / user of the unit should

make yourself familiar with the function,

installation and start-up of the unit through

these operating instructions.

It is essential that you follow these safety

notes and this information in order to ensure

trouble-free operation of the unit.

All the safety information is always intended

to ensure your personal safety!

The max. working pressure and the max.

permissible working temperature of the

pressure vessel are detailed on the type

plate.

The permissible working temperatures for

filter elements are given under Technical

data in these instructions.

Ensure that the permitted operational tem-

peratures are complied with, regardless of

the ambient temperatures prevailing at the

place of installation.

It is necessary to ensure that the unit is

equipped with the corresponding safety

and test devices to prevent the permissible

operating parameters from being exceed-

ed.

The pressure vessel must be at a safe

distance of min. 5 m to prevent heating

up in the event of a fire.

The pressure vessel has been designed for

a primarily static pressure loading with a

maximum of 1000 cycles to and from the

full load. Rapid changes of load with more

than 10% of the max. working pressure are

not allowed.

Ensure that the pressure vessel is not sub-

jected to vibrations that could cause fatigue

fractures.

The pressure vessel is not to be subjected

to stresses arising from traffic, wind and

earthquakes.

The medium used may not have any corro-

sive components that could attack the

materials of the pressure vessel in a way

that is not permitted.

All Installation and maintenance work on

the pressure vessel may only be carried

out by trained and experienced specialists.

For your safety

Functional elements

GB

Summary of Contents for P-EG

Page 1: ......

Page 2: ...DE GB FR NL IT ES PT DK SE FI GR ...

Page 4: ...A B C D E F G B A single ...

Page 5: ...A B B A D E G multiple H O O N I J M L K ...

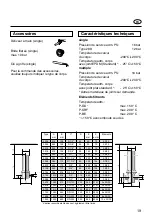

Page 6: ...2 0 bar 3 4 5 1 2 6 7 8 1 2 11 0 10 bar 12 13 14 15 single 1 2 16 1 1 2 9 10 ...

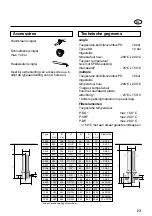

Page 7: ...2 0 bar 3 4 5 1 2 6 2 1 9 10 7 8 2 1 11 0 10 bar 12 13 14 15 16 2 1 17 multiple 1 ...

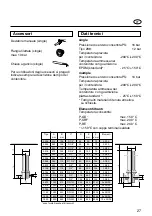

Page 48: ...48 A B C D E F G H I J K L M N O GR ...

Page 49: ...49 1 10 single 1 10 multiple 9 GR ...

Page 50: ...50 11 16 single 11 17 multiple P GS P SRF P BE 14 single DIN 11851 multiple DIN 2690 GR ...

Page 52: ......