ENLARGING THE 3MM HOLES TO 20MM

9

Figure 19

The 20mm Cutter (Figure 18)

The 20mm Guide Block (Figure 19)

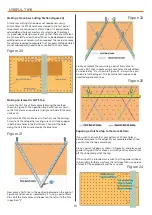

The 20mm Cutter has a 3mm spike at its tip. This spike has

no cutting action and so the cutter can only be used where a

3mm hole has previously been drilled through the material of

the bench top. It is recommended that there is no support

directly under the place where the 20mm cutter will emerge

as this can damage the cutter and reduce the quality of the

exit hole.

Please note

, to eliminate breakout in certain materials, we

recommend you should make a scribe cut using the 20mm

cutter on the underside before drilling from the face side, this

is done using the 3mm spike as a guide.

The 20mm holes are created using the 20mm Guide Block,

the special 20mm cutter and either the 3mm Guide Pins or

the Parf Locator Dogs.

The 20mm Guide Block is secured to the bench top being

created with either the 3mm Pins or the Parf Locator Dogs.

The 20mm Cutter can be fitted in two positions, shown in

Figure 15, which indicates which fixing method is used.

In order to position the 20mm Guide Block, insert the 20mm

Cutter and use its spike to locate the 3mm hole that is to be

enlarged. Then secure the Block with either the 3mm Pins or

Parf Locator Dogs.

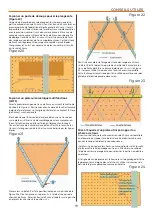

It may not be necessary to enlarge all of the 3mm holes and

it is worth thinking about the minimum number required to

create your bench top or track saw cutting station. When

using the Parf Guide System for the first time you may prefer

to clamp the 20mm Guide Block but as long as the 20mm

Guide Block is firmly held to the bench by Pins or Dogs then

no clamps will be required.

NOTE:

The 20mm TCT Drill Cutter is supplied with a stop collar

to avoid it dropping through to the floor at the end of a cut

after it is released from the drill.

NOTE:

It is recommended that a pecking action is used with

both the 3mm Drill and the 20mm Cutter. Cut a quarter of the

way through and withdraw the drill slightly, drill the next

quarter and withdraw and so on.

Figure 18