USEFUL TIPS

10

Figure 20

Figure 21

Figure 22

Figure 23

Figure 24

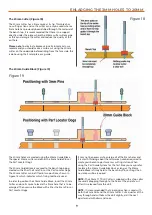

Making a Track Saw Cutting Station (Figure 20)

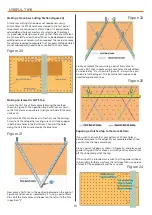

Making an Isometric MFT3 Top

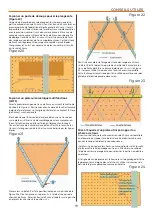

Squaring a Finished top to the Hole Pattern

A track saw cutting station does not require very many

20mm holes. If all the 3mm holes created in the first part of

the process are converted to 20mm holes it is impossible to

add additional holes accurately at a later stage. Therefore it

is a good idea to design your layout so that there are sufficient

3mm holes left to allow the Parf Sticks to be deployed to create

additional rows or columns when required. There are also some

3mm holes required to complete the Triangular Methods which

do not subsequently need to be converted to 20mm holes.

Create the first line of 3mm holes following the method

shown in Figure 21. Then position two Parf Sticks as shown

so that they form an equilateral triangle with side 10 (96mm)

units each.

As the two Parf Sticks intersect in fresh air, use the Joining

Screw to fix them together makng sure that it fully engages

in both 6mm holes in the Parf Sticks. Then drill the holes

along the Parf Sticks indicated by the blue lines.

If you wish to ensure that your pattern of 20 mm holes is

parallel or square to the edges of your completed bench top

you can trim the top accordingly.

Place a pair of tall dogs, as shown in Figure 24, and place your

guide rail against them. Make a cut with your tracksaw to trim

off the unwanted part of the top.

If the line of the intended cut is such that the guide rail need

to be slightly further away from the tall dogs then use a piece

of stock of the appropriate width as a spacer.

Now place a Parf Stick in the position indicated on the right of

Figure 22 and secure, as indicated by “2”, using a pair of 3mm

Pins. Drill the 3mm holes and repeat on the left with the Pins

in position “3”.

Finally, complete the rows using a pair of 3mm Pins to

secure a Parf Stick in place using 3mm holes already drilled,

as indicated by “4” as shown in Figure 23 - always use a pair

which are furthest apart. This Isometric technique can be

used for larger bench tops.