UBI EasyCoder 401 Linerless – Installation Instructions

5

POWER ON

BW

FW

LTS

LSS

R-END

P-6

P-607

P-606

WR-602

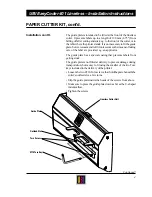

PAPER CUTTER KIT, cont'd.

Installation, cont'd.

1

/. The photoelectric sensors in the

cutter's LTS have a different sensitivity

than those in the front-fitted LTS. It is

important that the jumper on P-607 is

disconnected when upgrading an EC

401 LLT or when replacing the CPU

board in an EC 401 LLC.

• If the printer is, or has been, fitted with a label-taken sensor (LTS)

inside the front hatch, the following steps must be performed:

- Open the left-hand cover by removing six #T10 Torx screws.

- Disconnect the LTS cable from P-606.

- Remove the LTS by unscrewing the single #T10 Torx screw

that holds it to the print unit and carefully pulling out the cable.

- Connect the loose cable from the cutter interface connector

to P-606 on the CPU board.

- Check that the other cable from the cutter interface connector is

fitted on P-6 on the CPU board.

- Disconnect any jumper on P-607 on the CPU board

1

.

- Put back the left-hand cover.

EasyCoder 401

Power

Ready

Error

#T10 Torx Screws

#T10 Torx Screws

P-607 LTS Sensitivity Strap

(disconnect)

P-6 Cutter Connector

P-606 LTS Connector

WR-602 LTS Potentiometer