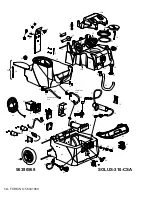

FORM NO. 56041868 -

15

SOLUS-310-CSA / 56380568

PART LIST

1

78

Light, green indicator

2

FP578

Switch, rocker, with cover

3

FP578

Switch, rocker, with cover

4

78B

Light, red, indicator

7

2093C

Switch plate, Solus 310

8

4404C

Mating bar

9

2105

Wheel, handle

9A

2106

Handle

10

1590

Grip, Handle

11

FP478

Float assembly, electric, water level

12

801D

Hinge pin

13

FP594

Tank, Vacuum

13A

VC BLK1

Cover, vacuum motors

14

2013A

Gasket, vacuum

14A

2013

Gasket, vacuum

15

408

Vacuum motor, 120V

15A

1589

Screen, 1/8 S/S mesh, vac inlet

16

2086A

Lid & ring, vacuum

17

1074

Gasket, vacuum lid

18

805

Chain, 8”

19

907

Hose barb, 1-1/2”

20

1130

Strap, Velcro, 9”

21

1060C

Cap, drain hose

22

1518

Hose Clamp

23

1060B

Hose, drain

24

FP582

Tank, Holding

25

FP545

Lid and chain, Holding Tank

26

909A

Latch strike

28

1113

Hose barb, 90°, 1/2” hose

28A

1115

Hose barb, 90°, 3/8” hose

29

925

Hose, 3/8” ID X 17”, bypass hose

31

166

Hose clamp

33

946

Hose, 1/2” ID X 20”, pump inlet hose

34

207A

Filter, pump inlet

36

See Miscellaneous **

37

918

Heat Sink plate

39

3000

Bracket, solenoid mounting

40

FP225

Vacuum Motor Control PCB

41

2014

Fan, 120V

42

2015

Guard, fan

43

2B1

Screw, 6-32 X 2-1/4”

44

1057B

Power Cord, 12/3, 25 ft

45

1062

Receptacle, AC power in

46

1476

Strap, 17”

47

2062

Solenoid, normally closed

49

FP336

PCB mounting track, 4”

50

923B

Dual Cord Sensor PCB

ITEM PART No

DESCRIPTION

ITEM

PART No.

DESCRIPTION

120V

MISCELLANEOUS PARTS

51

198

Hose Clamp

52

2060

Motor, AC, for pump

53

FP____

Pump complete, no mtr

54

FP542

Hose assembly, pump to gauge

55

801

Hinge pin

56

27A

Axle Cap

57

2092

Wheel, 12”

58

910-23.75

Axle,

60

BUPE-BLK

Base

61

CUPE-BLK

Castor Plate, BLack

62

905

Castor, 4”

63

2164

Gauge, Pump pressure, 300 PSI

64

928

Louver, 3”, gray

65

908

Latch

66

45

Quick Disconnect, male. 1/4 p.t.

67

116A

Bushing, fiber

68

115

Washer, fiber

70

168

“T” Brass

71

92A

Nipple, 1/4 p.t. S/S

72

FP___

Heat Exchanger, complete

73

455

Mount bracket, heater

74

945

Valve, bypass

77

1278A

Hose, heater inlet

78

313

Hose, S/S, braided, heater outlet

**FP194E

Heat repair kit includes thermistor control,

thermistor probe & cutout

950CP

Pump rebuild kit, valves and o-rings

250

Pump rebuild kit, piston and seals

FP____

Pump & motor, complete, with bypass

2110

Circuit breaker

2111

Terminal Block