106636-02 - 12/19

21

X-2

Installation, Operating & Service Manual

9

System Start-up and Checkout

(continued)

CAUTION

Avoid operating boiler in an environment where

saw dust, loose insulation fibers, dry wall dust,

etc. are present. If boiler is operated under

these conditions, burner interior and ports

must be cleaned and inspected daily to ensure

proper operation.

!

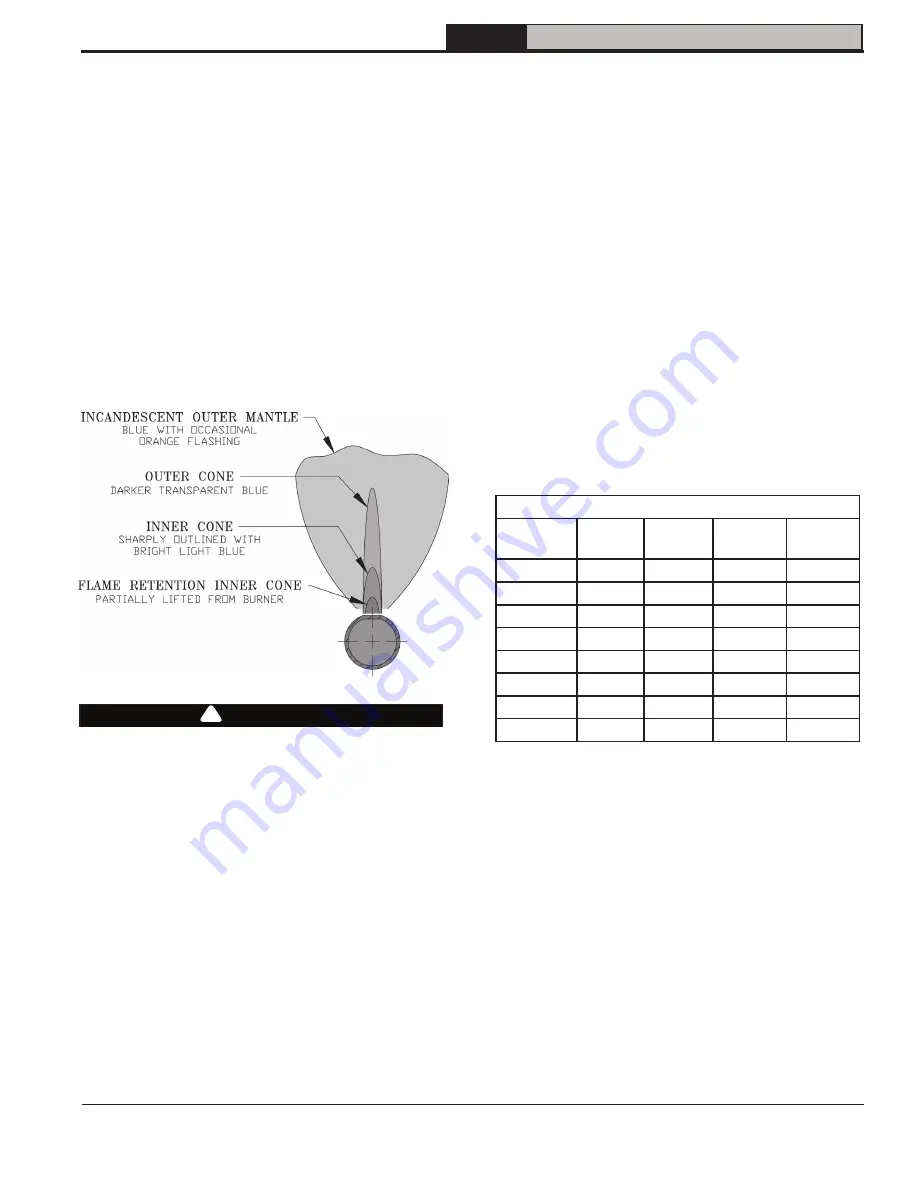

J. Check Main Burner Flame (see Figure 9-6)

1. NORMAL FLAME:

a. Clearly defined inner cone with no yellow

tipping.

b. Orange-yellow streaks caused by dust

should not be confused with true yellow

tipping.

2. ABNORMAL FLAME (if found, check inlet and

outlet gas pressure. Procedure found in

following steps):

a. Over fired - large flame

b. Under fired - small flames

c. Lack of primary air - yellow tipping on

flames.

K. Check gas inlet pressure

1. While boiler and all other gas appliances

are not firing, gas inlet pressure should not

exceed ½ psig.

2. While boiler and all other gas appliances

are firing, gas inlet pressure must be

between minimum and maximum shown

on rating label.

L. Check gas outlet (manifold) pressure

1. Install manometer on 1/8" outlet pressure

tap on gas valve (see Figure 9-3). Use

of shutoff valve between manometer and gas

valve can prevent pressure surge that blows

out manometer fluid.

2. Adjust regulator on gas valve so manifold

pressure matches values listed on rating label.

3. Turning regulator adjustment screw

clockwise (

) increases pressure.

4. Turning regulator adjustment screw

counterclockwise (

) decreases pressure.

M. Check gas input rate to boiler

1. When checking rate, ensure all other

appliances connected to same meter as

boiler are off.

2. Input ratings shown on boiler rating label

can be used for elevations up to 2,000 ft. For

elevations 2,000 ft. or higher, reduce input

rate to 4 percent per 1,000 ft. above sea level.

Do not install at elevations above 12,000 ft.

See Table below.

Figure 9-6: Main Burner Flame

N. Measure carbon monoxide (CO) level in vent after

5 minutes of main burner operation. CO should

not exceed 400ppm air free.

O. Check vent damper operation.

Vent damper must be in open position when

appliance main burners are operating.

Input (MBH)

Boiler

Model

Rating

Label

5,000 ft. 7,000 ft.

10,000

ft.

X-202

38

30.5

27.5

23

X-203

70

56

50

42

X-204

105

84

76

63

X-205

140

112

101

84

X-206

175

140

126

105

X-207

210

168

151

126

X-208

245

196

176

147

X-209

280

224

202

168