13

111299-06 - 9/22

SteamMax

Knock-Down Assembly Instructions

DANGER

• Use precautions and appropriate rigging

apparatus when moving heavy objects.

• Use proper Personal Protective Equipment (PPE)

during assembly.

5

Split Section and Base Assembly

See Figures 5-1, 5-2, 5-3 and 3-2 for References.

1. Either left section assembly or right section

assembly can be secured first. Left section

assembly will be secured first for purposes of this

instruction.

NOTICE:

Insulation between base and section

assembly is not used. A high temperature silicone

RTV will be used to seal base/section assembly

joint after section assemblies are joined on base.

See step 19.

2. Screw (2) 5/16-18 hex head bolts,

Item 1

, into

holes in base.

3. Lower left assembly,

Item 2

, onto base with bolts

centered in assembly slots.

4. Tighten 5/16-18 nylon locking nuts and washers,

Item 3

, onto bolts.

5. Thoroughly clean nipples,

Item 4

, and nipple

ports with a de-greasing solvent.

6. Evenly coat nipples and nipple ports with

provided Loctite® 592.

7. Place nipples in nipple ports and bump carefully

with a wooden block to set.

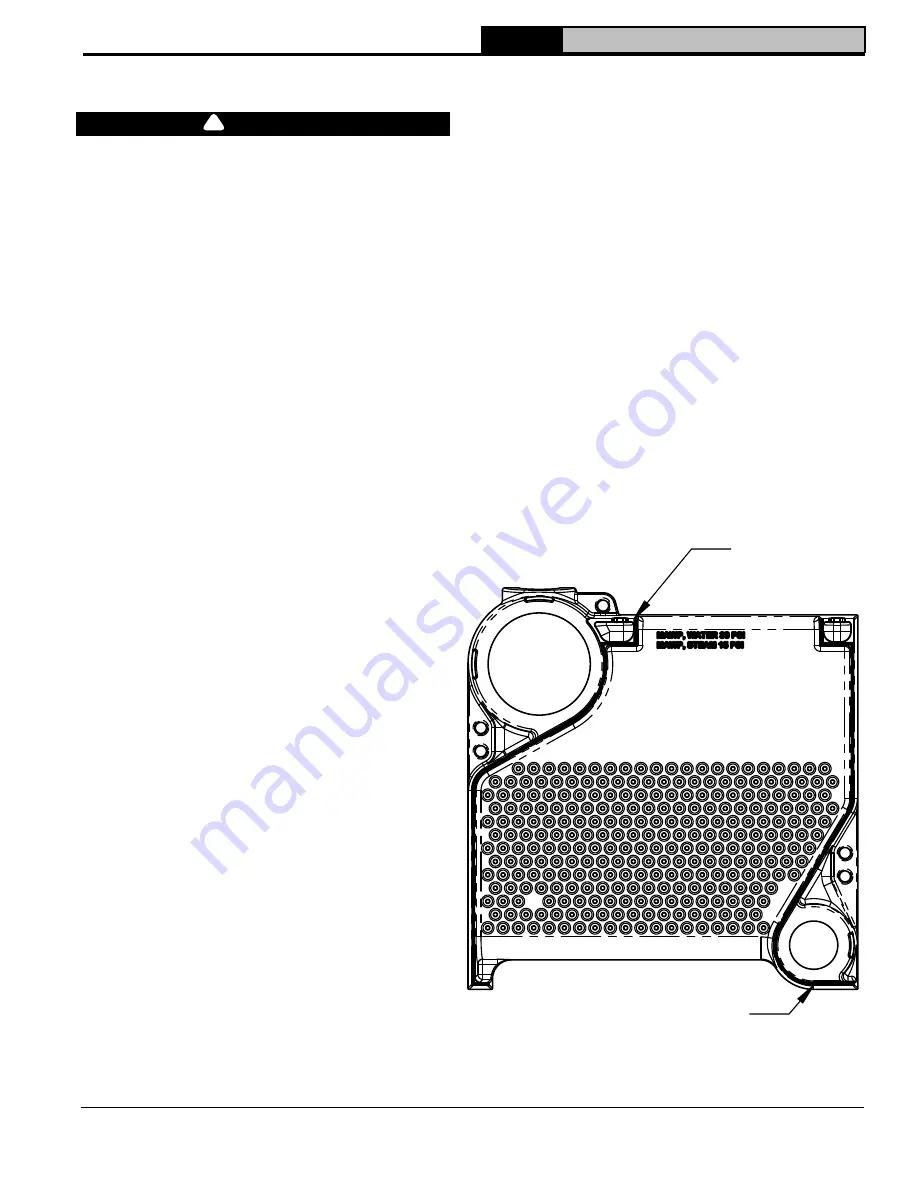

8. Apply provided SIL-BOND RTV 6500 to flue way

joint. See Figure 5-1.

9. Place right section assembly,

Item 5

, onto base

as close to left section assembly as possible

aligning nipples to nipple ports.

10. Screw together enough 3/4-10 x 11" draw rod

using coupling nuts,

Item 6

, to pass through

section assemblies,

Items 2 and 5

, draw plates,

washers & nuts,

Item 7

, on both sides. Two draw

rods are required, one through upper nipple port

and other through lower nipple port.

11. Keep draw rod threads lubricated to reduce

friction for easier assembly.

12. Draw section assemblies together slowly and

evenly. Alternately tighten upper and lower draw

rods. Tighten each draw rod a little at a time so

sections are evenly spaced. Either base assembly

and/or section assemblies may require adjusting

to maintain nipple and nipple port alignments.

13. Tighten until sections meet iron-to-iron. Small

gaps, typically less than 1/16", between sections

after assembly are normal.

NOTICE:

Do not loosen or remove draw rods until

tie rods are secured.

14. Screw (2) 5/16-18 hex head bolts through base

holes and section assembly slots on right side.

15. Tighten 5/16-18 nylon locking nuts and washers

onto bolts.

16. Place 3/8-16 x 7-3/4" long tie rods,

Item 8

, through

top lug holes at upper and lower nipple ports.

17. Tighten 3/8-16 nut and washer,

Item 9

, onto each

end of a tie rod until hand tight. This will allow for

thermal expansion.

18. Remove draw rods.

19. Hydrostatically test section assembly.

NOTICE:

It is essential that hydrostatic testing

be done before sealing block to base (step

20) and before canopy, jacket, controls, and

piping are installed. See Hydro-Test Section for

procedure.

20. Apply provided SIL-BOND RTV 6500 to entire

perimeter of base/section assembly joint. See

Figure 5-2.

Flue Way

Joint

Flue Way

Joint

Figure 5-1: Assembly Section Flue Way Joint

Apply Silicone

Here

Apply Silicone

Here

!