37

H.

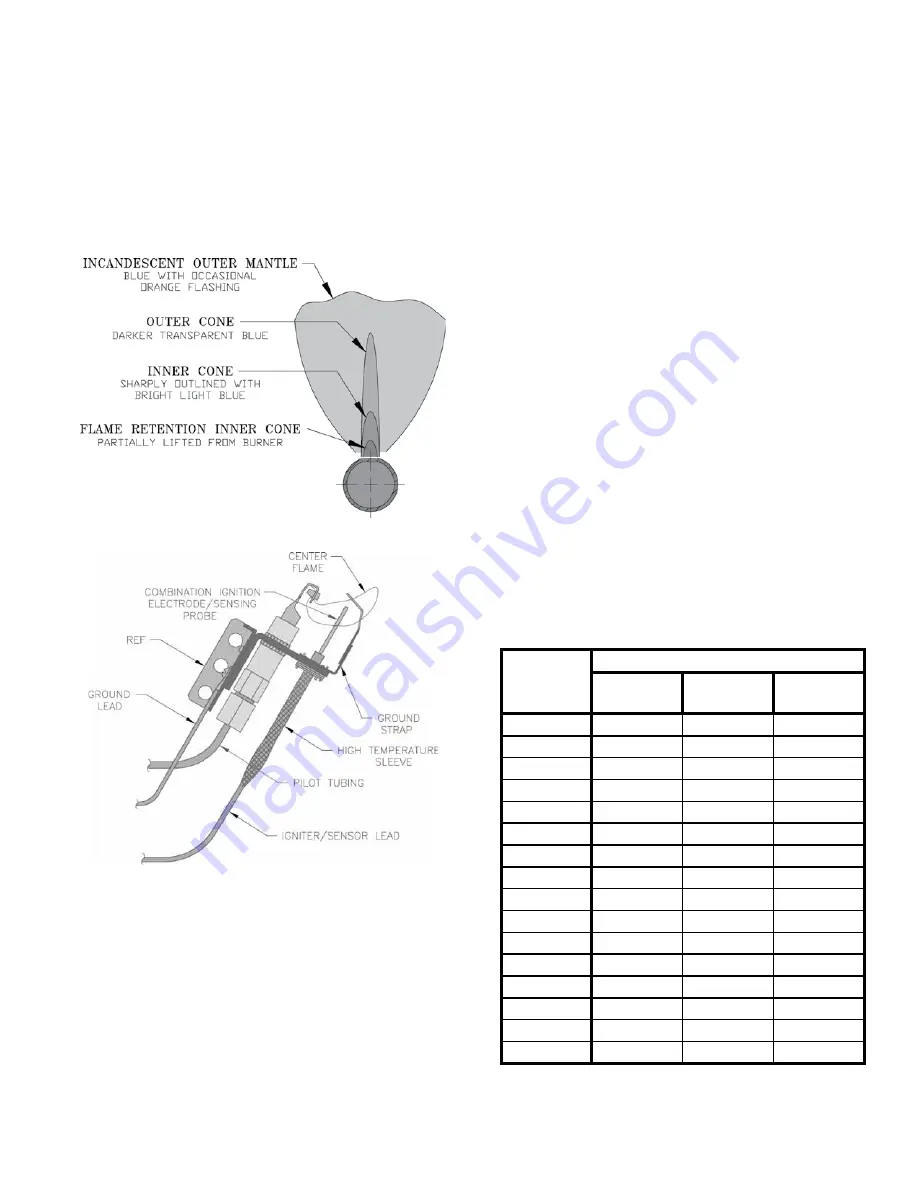

Check pilot burner flame.

See Figure 24. Flame

should be steady, medium hard blue enveloping 3/8 to

½ inch of sensing probe.

I.

Check main burner flame.

See Figure 23. Flame

should have clearly defined inner cone with no yellow

tipping. Orange-yellow streaks should not be confused

with true yellow tipping.

Figure 23: 1 Inch Main Burner Flame

Figure 24: Pilot Burner Flame

J

. Check thermostat operation.

Raise and lower

temperature setting to start and stop boiler operation.

K.

Check ignition control module shut-off.

Disconnect

pilot lead wires from gas valve. If burners do not

shutdown, determine cause of malfunction. Replace

necessary items and check operation.

L.

Check low water cutoff

(if so equipped).

1. Adjust thermostat to highest setting.

2. With boiler operating, open drain valve and slowly

drain boiler.

VIII. SYSTEM START-UP

(continued)

3. Main burners and pilot burner will extinguish and

blower will stop when water level drops below low

water cutoff probe. Verify limit, thermostat or other

controls have not shut off boiler.

4. Adjust thermostat to lowest setting. Refill boiler.

M.

Check limit.

Jumper Thermostat connections in boiler wiring

harness. Allow burners to operate until shutdown by

limit. REMOVE JUMPER.

N.

Adjust gas input rate to boiler.

1. Adjust thermostat to highest setting.

2. Check manifold gas pressure. See Table 5 or rating

label located in the boiler’s vestibule compartment.

Adjust gas valve pressure regulator as necessary

(turn adjustment screw counterclockwise to

decrease manifold pressure, or clockwise to increase

manifold pressure). If pressure cannot be attained,

check gas valve inlet pressure. If less than minimum

indicated in Table 5 or boiler’s rating label, contact

gas supplier for assistance.

3. Clock gas meter for at least 30 seconds. Use Table

10 to determine gas flow rate in Cubic Feet per

Hour.

Seconds

for One

Revolution

Size of Gas Meter Dial

One-Half

Cu. Ft.

One

Cu. Ft.

Two

Cu. Ft.

30

60

120

240

32

56

113

225

34

53

106

212

36

50

100

200

38

47

95

189

40

45

90

180

42

43

86

172

44

41

82

164

46

39

78

157

48

37

75

150

50

36

72

144

52

35

69

138

54

33

67

133

56

32

64

129

58

31

62

124

60

30

60

120

Table 10: Gas Flow Rate in Cubic Feet

Per Hour

Summary of Contents for PVG3

Page 14: ...14 Figure 4 Horizontal Vent Installation III Venting continued...

Page 16: ...16 Figure 7 Attic Offset Figure 6 Vertical Vent Installation III Venting continued...

Page 29: ...29 Figure 17 Wiring Connection Diagram VI Electrical continued...

Page 31: ...31 Figure 19 Circulator Zoned System Wiring Diagram VI Electrical continued...

Page 32: ...32 Figure 20 Zone Valve Zoned System Wiring Schematic VI Electrical continued...

Page 34: ...34 Figure 21 Modular Boiler Piping VII Modular Installation continued...

Page 36: ...36 Figure 22 Operating Instructions VIII System Start up continued...

Page 51: ...51 Figure 29 Flue and Burner Cleanout 1 Burner XI Service continued...

Page 54: ...54 XII Repair Parts continued...

Page 56: ...56 XII Repair Parts continued...

Page 60: ...60 XII Repair Parts continued...

Page 67: ...67 SERVICE RECORD DATE SERVICE PERFORMED...

Page 68: ...68 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...