USER GUIDE

u-line.com

Cleaning

Under normal conditions cleaning should be done

when the display shows

CL

. You may initiate a

cleaning cycle at any time by pressing and holding

the clean button for 10 seconds.

0 1

will appear

in the display indicating the start of the cleaning

process.

Failure to clean may reduce the quality and quantity of ice

produced. Once the clean cycle begins, it can be canceled

by pressing three times. Press once more to start

making ice. The clean cycle will automatically cancel if user

fails to activate control at steps 2, 3b, and 5b within 2 hours.

Required for cleaning:

• Clean potable water

• Bucket and cleaning sponge

•

Internal water filter (if applicable) —

ULANUGGETFILTER**

•

SafeCLEAN Plus™ Cleaner — ULANUGGETCLEAN**

•

Hose (7⁄16

” ID x

9⁄16” OD) and funnel

◦

Register your product at u-line.com and receive

a free cleaning kit - ULANUGGETCLEANKIT**

(cleaner, hose, & funnel)

** available for purchase at u-line.com or your local dealer

Need more cleaner? Visit u-line.com

CAUTION

!

Use only SafeCLEAN Plus™ Cleaner. Use of any

other cleaner may damage the finish of the

evaporator and will void the warranty.

Follow safety and handling instructions printed on

the SafeCLEAN Plus™ bottle.

Notice:

Select models include a water filter. The filter

must remain in place when using and cleaning

the machine. The filter is designed to filter out

scale, sediment, particles and cloudiness as well

as reduce chlorine and other off tastes and odors.

U-Line recommends replacing the filter (Part No.

ULANUGGETFILTER) when you clean your machine.

The filter is available at u-line.com.

1. Press and Hold for 10 seconds

a.

0 1

will appear in the display

b. Remove access shield

c. Remove all ice in bin

d. Remove any ice protruding from the ice dispenser

tube.

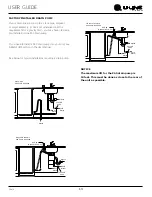

2. Insert the end of the cleaning tube into the ice

dispenser; slowly pour in approximately 1 quart of

hot (min. 100º F) potable water. This will melt ice

inside the dispenser tube. It is normal for some water

to flow from the ice dispenser tube and exit from the

vent tube while pouring. Omit this step if no ice is in

the ice dispenser tube.

3. Press and release

a.

02

will appear in the display

b. Mix 4 ounces of SafeCLEAN Plus™ with 2 quarts of

potable water.

4. Wait until

03

appears in the display

a. Using the funnel and cleaning tube, slowly pour

3⁄4

of the cleaning solution into the dispenser

tube. Air and some water will exit the vent tube.

Remove cleaning tube. (Optional - for deeper

cleaning, allow solution to soak for 60 minutes)

b. Press and release

5

.

04

will appear in the display

a. The machine will circulate the solution, cleaning

and sanitizing the internal components, for

approximately 20 minutes.

b. While the machine is circulating the cleaning

solution, use

1⁄2

of the remaining cleaning solution

and a sponge to wipe down the inside of the ice bin

and scoop. Rinse with clean potable water.

Cl

Cleaning Tube

and Funnel

Ice

Dispenser

Tube

Vent Tube

25