TCF&B ES-52

3

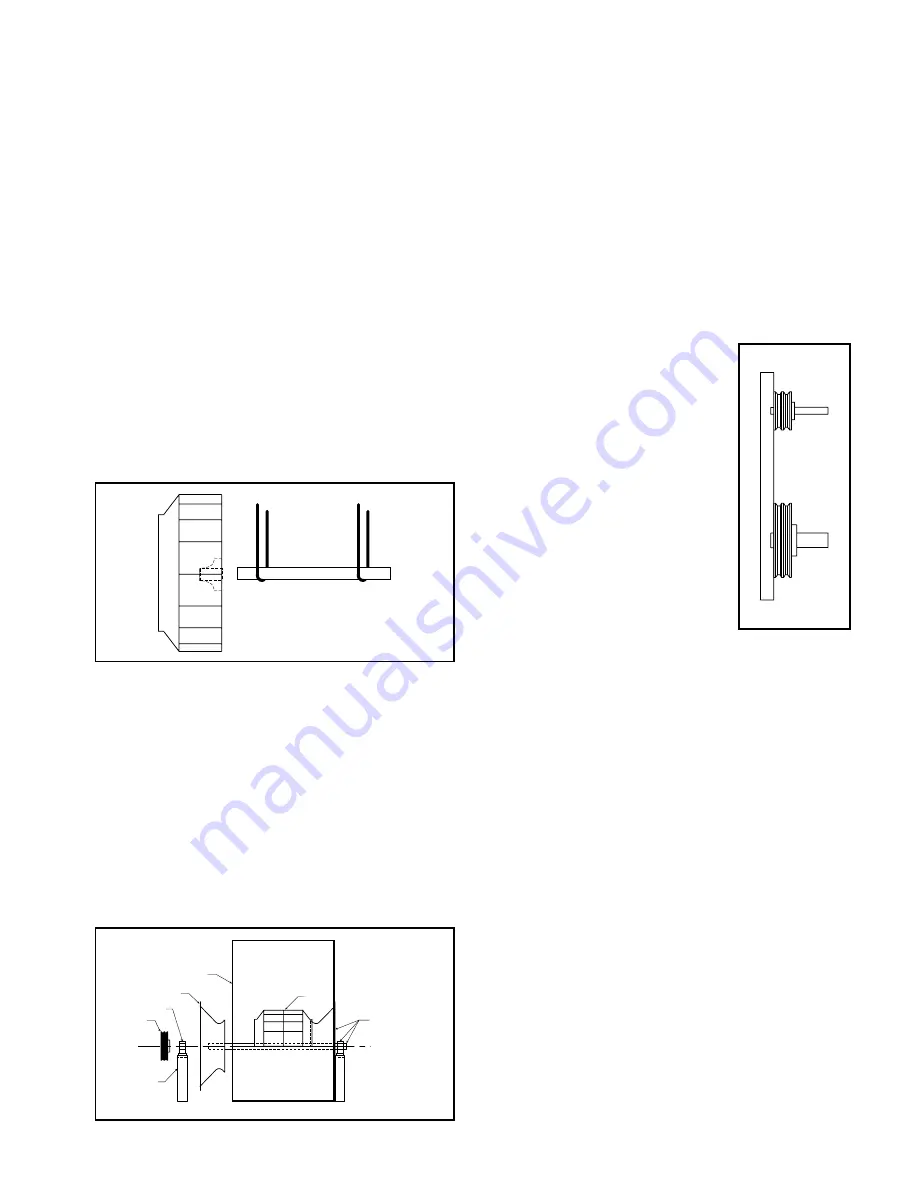

Figure 3. Drive Component Assembly

not touch clean areas of shaft with hands. Perspiration

can cause rust or pitting over time.

b. Remove keys from shaft.

c. Clean inside of wheel bore with solvent. Make sure set

screws will not interfere when inserting shaft into

wheel bore.

6. Arrangement 1, 9 or 10: Drive Component Assembly (See

Figure 3):

a. Insert shaft into wheel from back side of wheel.

b. When shaft is flush with wheel hub, put key into key-

way and tighten wheel set screws.

c. Insert shaft through opening in drive side. (If split

housed unit, lower into position.)

d. Install bearings onto shaft. Do not tighten bearing set

screws at this time. The bearing housing should be

perpendicular and the bearing base parallel to the axis

of the shaft to prevent loads caused by misalignment.

e. Mount assembly, bolt bearings to drive stand. Shaft

must be parallel with side of bearing pedestal. After

aligning and bolting bearings to pedestal, tighten

bearing set screws. Continue with step 8.

7. Arrangement 3 (Split-housed) units ( See Figure 4):

a. Parts on DWDI units are assembled in the following order

as viewed from opposite drive side: Bearing

bar assembly and opposite bearing, funnel, (housing

side), wheel, (housing side), funnel, drive side

bearing bar assembly, drive bearing and sheaves. Mount

bearing bar assembly to housing. Center wheel in funnels.

b. Parts on SWSI are assembled in the following order as

viewed from opposite drive side: Bearing bar assembly

and opposite bearing, funnel, (housing side), wheel,

(housing side), drive side bearing bar assembly, drive

bearing and sheaves. Mount bearing bar assembly to

housing. (See Figure 6 for wheel-funnel overlap.)

c. Assemble parts in above order on shaft.

Shaft

Centerline

Bearing

Pedestal

Sheave

Bearing

Inlet Funnel

Housing Side

Wheel

Assembled Bearing,

Shaft, Funnel, and

Housing. Frame

Angles Not Shown.

Figure 4. Split-housed Drive Component Assembly

d. Move assembly into position. Lightly bolt bearings

into place.

e. Shaft should be parallel with discharge of housing.

Move bearings to accommodate.

f. Level shaft; shim bearings if required. Tighten bearing

set screws.

8. Install motor on base. Carefully align shafts for drive

installation.

9. Mount drives as follows:

a. Slip (do not pound) proper sheave onto corresponding

shaft as close as possible to bearing. CAUTION:

PLACING FAN SHEAVE ON MOTOR CAN OVER-

SPEED WHEEL AND CAUSE STRUCTURAL FAIL-

URE.

b. Align sheaves with a straightedge

extended along perimeters of both

sheaves, just making contact in

two places on outside the perime-

ters of both sheaves (see Figure

5).

c. Tighten down sheave bolts.

d. Install a matched set of belts.

Slide the motor to obtain slack

and tighten belts. Using a pry

will damage belts.

e. Tighten belts to proper belt ten-

sion. Ideal tension is just

enough tension so that belts do

not slip under peak load.

Recheck sheave alignment.

f. After initial installation of belts,

recheck belt tension again after

a few days to adjust belt ten-

sion. (New belts require a break-

in period of operation.)

10. Install any safety devices or accessories supplied.

(Accessories commonly used are inlet vanes, shaft

seals and shaft coolers, plugs, dampers, and inlet or

discharge screens. Refer to appropriate documents in

appendix.)

11. Grout may now be applied. Grout is used to distribute

loads and should not be used as the sole support of

any rotating equipment.

12. When connecting the fan to the system, it is recom-

mended that the inlet and discharge be isolated from the

system with flex connections (where practical) to block

transmitted vibration. All duct connections to the fan

should be independently supported. Do not use fan to

support duct.

Fan Operation - Safety

For general safety practices for air moving equipment, see

AMCA Bulletin 410.

Twin City Fan & Blower has many safety accessories

available. These safety devices include (but are not limited

to) belt guards, shaft guards, inlet and discharge screens.

The use, abuse, or non-use of safety devices is the respon-

sibility of the purchaser.

Facility-related safety conditions include fan accessibility

and location. How easily can non-service personnel access

the unit? Is the fan in a hazardous duty environment? Was

the unit ordered for this duty? Other concerns must also be

addressed. All fans should be powered through switches

which are easily accessible to service personnel from the

Figure 5.

Sheave Alignment