14

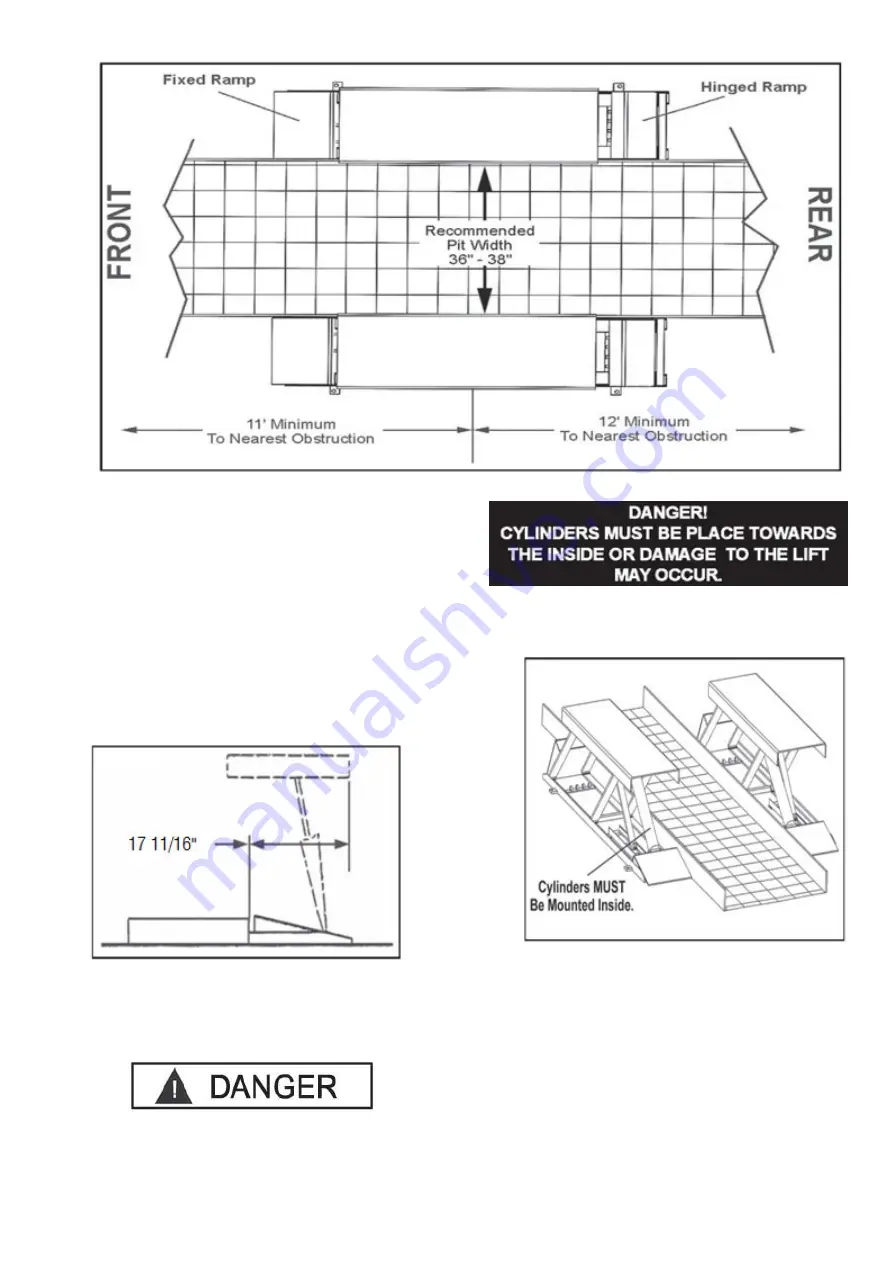

Fig. 3.1

STEP 3

(Locating Unit)

NOTE:

The maximum recommended width between pads is

38”. Consult the factory for applications that require

installations wider than 38”.

1. Before selecting an installation site, check for

proper clearance and/or obstructions. (See Fig

3.1)

2. Remember that the lift moves rearward

approximately 14” when raised. (See Fig 3.2)

Fig. 2.3

3.

Always consult the building engineer before

installing this lift to make sure the floor is capable

of sustaining the load.

4. After selecting a site, place each unit in position.

The Cylinders MUST be placed towards the inside.

(See Fig 3.3)

Fig. 3.3

5. It may be necessary to remove the tire rail

adjacent to the lift pad and overhang the edge of

the rail to maintain the 36”- 38” recommended

width between pads.

6. Each lift pad can overhang the edge of the pit a

maximum of two inches on each side as long as

the inside anchor bolt can be installed properly.

Tire Rail

Summary of Contents for PL6K

Page 1: ...PL6K 6600 POUND CAPACITY LOW RISE PIT Installation and Operation Manual REV A 062813 ...

Page 2: ......

Page 3: ......

Page 25: ...25 6600Lbs 3000Kg 3300Lbs 1500Kg 3300Lbs 1500Kg ...

Page 26: ...26 ...

Page 34: ...34 MAINTENANCE RECORDS ...

Page 35: ...35 ...