20

5. Turn the bottom nuts to tension the belt(s)

while holding the top nuts. This action

moves the indicator upward. Continue

tightening the bottom nuts until the indicator

pin is again at the top of the indicator slot.

6. Replace/close and latch the front panel/

doors. Lower the top panel and latch.

7. Unlock the power and start your Qube.

8. Resume normal operation.

6.4 PREVENTATIVE MAINTENANCE

A good maintenance program will add years of

service to your blower. A newly installed blower

should be checked frequently during the first

month of operation, especially lubrication. Check

oil level in both the drive end and gear end of

the blower and add oil as needed. Complete

oil changes are recommended every 1000

operating hours, or more frequently depending

on the type of oil and oil operating temperature.

The following is recommended as a minimum

maintenance program.

DAILY

WEEKLY

MONTHLY

1. Check and maintain oil level,

and add oil as necessary.

2. Check for unusual noise or

vibration (See

Troubleshooting

)

1. Clean all air filters. A

clogged air filter can seriously

affect the efficiency of the

blower and cause overheating

and oil increased oil usage.

Replace if necessary.

1. Inspect the entire system for leaks.

2. Inspect condition of oil and change if necessary.

3. Check drive belt tension and tighten if

necessary.

4. Inspect check valve.

6.5 LONG TERM STORAGE

Any time the blower will be stored for an extended period of time, you should take make sure that it is

protected from corrosion by following these steps:

1. Spray the interior (lobes, housing and end plates) with rust preventative. This should be repeated as

conditions dictate and at least on a yearly basis.

2. Fill both end covers completely full of oil.

3. Firmly attach a very prominent tag stating that the end covers are full of oil and must be drained and

refilled to proper levels prior to startup.

4. Apply a rust preventative grease to the drive shaft.

5.

Spray all exposed surfaces, including the inlet and discharge flanges, with rust preventative.

6. Seal inlet, discharge and vent openings. It is not recommended that the unit be set in place, piped to

the system, and allowed to remain idle for a prolonged amount of time. If any component is left open

to the atmosphere, the rust preventative will escape and lose its effectiveness.

7. During storage, ensure that the blower does not experience excessive vibration.

8. Attach a desiccant bag to either of the covers to prevent condensation from occurring inside the blower.

Make sure any desiccant bag (or bags) is so attached to the covers that they will be removed before

startup of the blower.

9. Store the blower in an air conditioned and heated building if at all possible. At least insure as dry

conditions as possible.

10. If possible, rotate the drive shaft by hand at least monthly in order to prevent seals from setting in one

position.

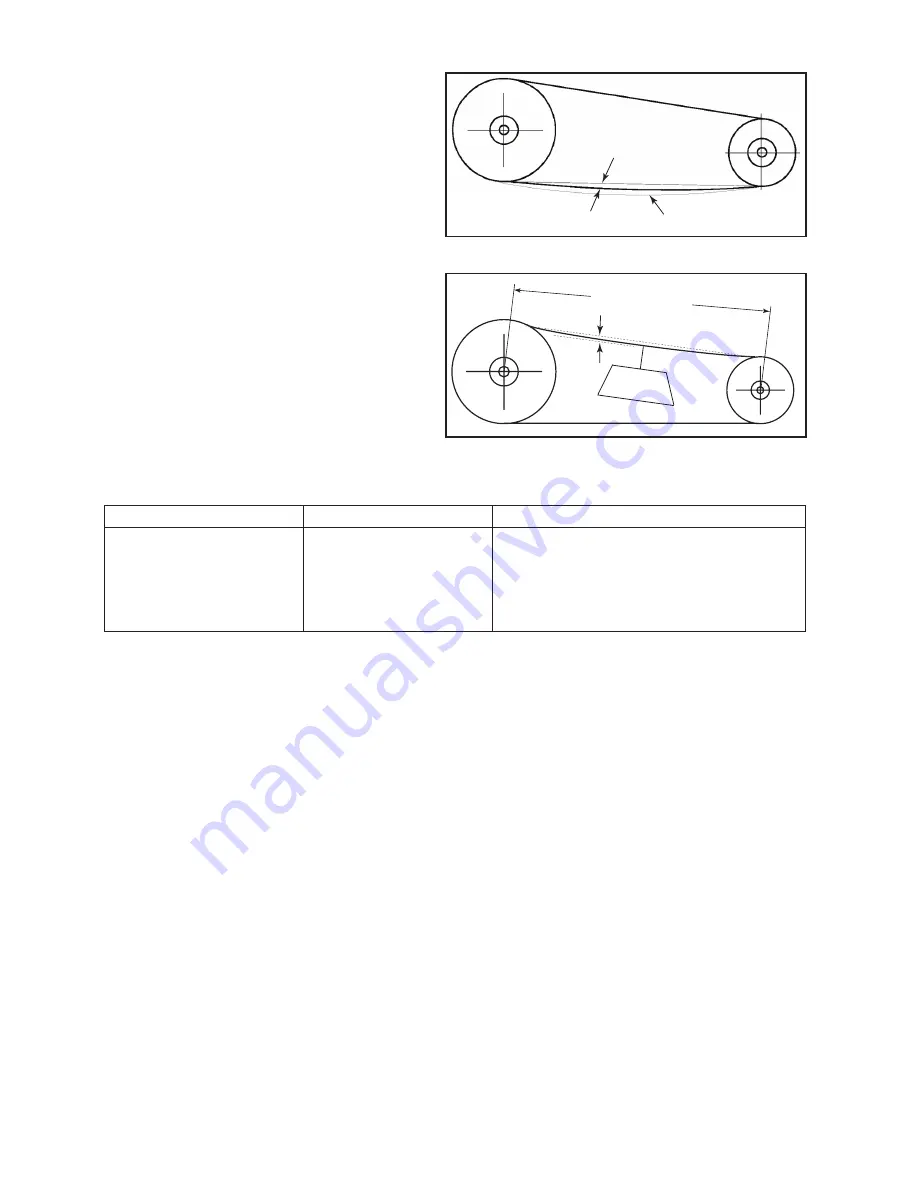

Too Tight

Slight Bow

Too Loose

20/64” = 5/16”

(8 mm)

20”

(50.8 cm)

8-10 lbs.

(3.6-4.5 kg)

Too Tight

Slight Bow

Too Loose

20/64” = 5/16”

(8 mm)

20”

(50.8 cm)

8-10 lbs.

(3.6-4.5 kg)

Figure 7 - General appearance of a V-Belt drive

Figure 8 - Setting of proper tension for a V-Belt drive