18

DISASSEMBLY

KMBD-540

KMBD-720

KMBD-850

KMBD-1600

KMBD-2000

KMBD-2700

1) Disconnect cooling water lines (274 & 181). Do not disturb the

large hex head screw (97). If it is removed, loosened, or water is

detected in drain oil, the coil assembly must be retested as

described in the assembly procedure.

2) Drain oil from both ends of booster and remove port fittings (38

or 48).

3) Remove motor and drive coupling.

4) Remove bolts (93) and take off seal housing (91) using jack

screws.

5) Remove cover (6), mating ring (76) will come off with cover.

6) Remove drive shaft screws (66) and locks (65). Tap shaft lightly

to remove.

7) Remove gear lock nuts and washers (35 & 36). Models KMBD-

850C, 1200C, 1600C, 2000C, and 2700C (horizontal flow series,

top drive only). Remove cap screws (396), washers (136 & 80),

and oil slinger (20) if furnished. These items are not shown on

exploded view but are listed on parts list.

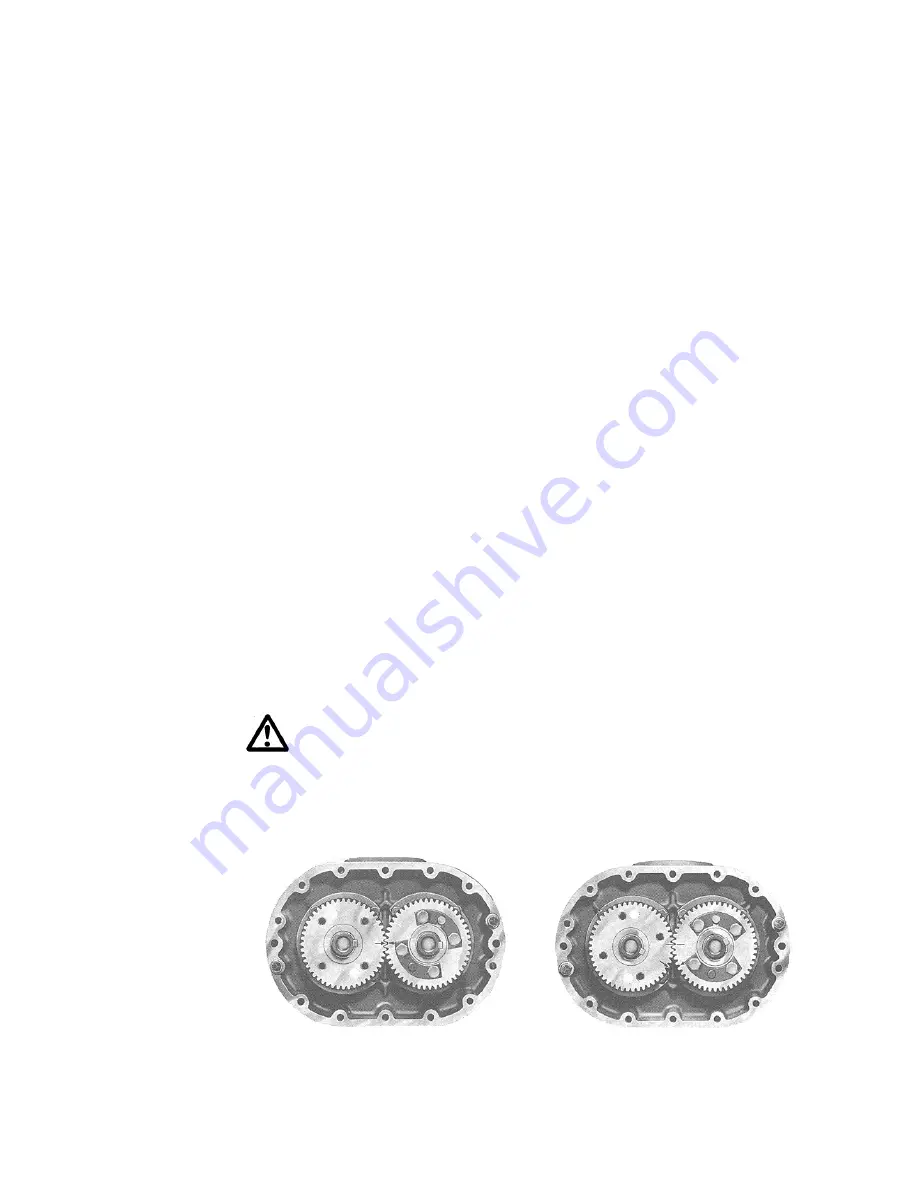

8) Position the timing gears for pulling by first matching the timing

marks on the gears. See Figure 10A. Turn the drive gear

clockwise five teeth and mark a matching reference line on each

gear as shown in Figure 10B. The rotor lobes are now in their

most open position. Using a gear puller, the driven gear (left

hand helix) may now be removed without jamming the rotors.

This gear is in two parts – the gear rim and hub. It is not

necessary to disassemble. Do not allow the gears to move from

matched reference line while pulling. Use a light rocking motion

while pulling the gear to insure that the lobes have not jammed.

WARNING:

Failure to properly pull this gear could result in

damage to rotor keyway or a bent rotor shaft. Never use

excessive force.

9) Remove drive gear. It is not necessary to remove keys from rotor

shafts.

Figure 10A

Figure 10B