6

Operation (with Heater)

START-UP

1.

Reference the Performance Curves section

(see page 6)

for operational parameters before attempting to

operate heater(s).

2.

Turn on air and set pressure or flow to desired operating level.

3.

If using a closed loop system, turn on power to the temperature and power controller, then set the desired

temperature on the temperature controller. If using an open loop system, increase power to the heater

through the power controller until the desired temperature is attained.

SHUT-DOWN

1.

Turn off Main Power circuit breaker, or disconnect MAIN POWER line.

2.

Allow air to continue to flow for a minimum of 1 minute or until exit air temperature is 300

°

F (150°C) or less

for safety. Continue airflow longer as necessary to prevent burn hazard to personnel.

3.

Turn off air to the system.

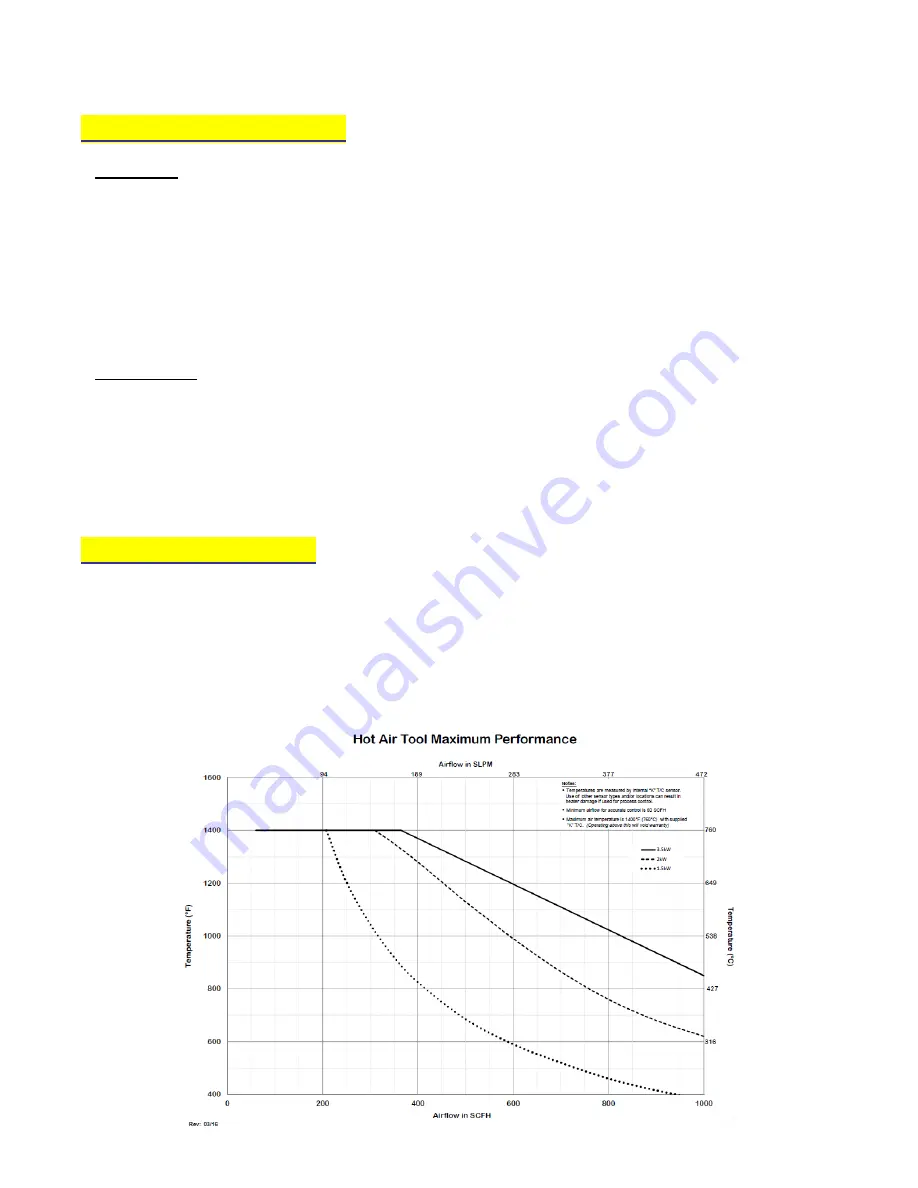

Performance Curves

The attached performance curves show exit air temperatures at different airflows and voltages. Pressure

readings (longer dashed lines) are measured at the inlet to the heater with no entrance or exit restrictions. Solid

lines indicate safe, normal-life operating conditions. The shorter dash lines indicate marginal, shorter-life

operating conditions leading to premature burnout. With a known flow (or pressure) at the heater entrance, follow

the flow (or pressure) line across until it meets the desired temperature curve. Drop a line straight down to

intersect the x-axis. This point, along the “Heater volts – true RMS” axis, represents the voltage required to

generate the desired exit air temperature at the chosen flow rate (inlet pressure).

Summary of Contents for F068462

Page 7: ...7 ...