Turbo BBQ Replacement Parts List

SKU#

Description

QTY

CG

3

T

CBN

CG

3

T

DBRN

CG

4

T

CBN

CG

4

T

DBRN

CG

5

T

CBN

CG

5

T

DBRN

IT

E

M

31

1

1

1

161485

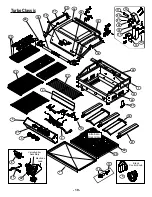

Side Panel - Left (Style 3)

32

1

1

1

161490

Side Panel - Right (Style 3)

1

161504

Back Panel - 3 Burner (Style 3)

1

161519

Back Panel - 4 Burner (Style 3)

1

161524

Back Panel - 5 Burner (Style 3)

1

253161

Shroud Black w/Cmpts - 3 Burner

1

253179

Shroud Black w/Compts - 4 Burner

1

266189

Shroud Black w/Compts - 5 Burner

35

1

1

1

161579

Hood Hardware Pack Assy (Style 3)

1

254011

26" S/Steel Handle

1

254029

31" S/Steel Handle

1

254037

39" S/Steel Handle

37

1

1

1

1

1

1

156733

Turbo Badge

38

1

1

1

218347

Hood Thermometer - Turbo Elite

39

1

1

1

120776

Hood Thermometer - Turbo Classic

1

1

1

1

1

1

161603

Crossfire-Stainless Steel 3 Burner

1

1

1

1

1

1

161618

Crossfire-Stainless Steel 4 Burner

1

1

1

1

1

1

161623

Crossfire-Stainless Steel 5 Burner

41

2

2

2

2

2

2

163133

Clip for Crossfire

42

1

1

1

1

1

1

163207

Lighting Instruction Decal

43

2

2

2

2

2

2

162772

Hood Buffer

1

171330

26" Warming Rack - Porcelain Enamel

1

172197

31" Warming Rack - Porcelain Enamel

1

196071

39" Warming Rack - Porcelain Enamel

1

269787

26" Warming Rack - Stainless Steel

1

269795

31" Warming Rack - Stainless Steel

1

269803

39" Warming Rack - Stainless Steel

46

2

2

2

269811

Handle Brackets for S/Steel Hood

1

269829

Handle 3 Bnr S/Steel Hood

1

269837

Handle 4 Bnr S/Steel Hood

1

269845

Handle 5 Bnr S/Steel Hood

48

3

3

4

4

5

5

269928

Valve- Turbo Flame Thrower

49

1

1

1

244061

Black Handle Bracket Assembly

50

2

2

3

3

4

4

287326

Heat Shield S/Steel

1

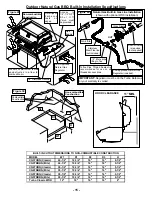

297150

Rear Burner Small - Black

1

1

297168

Rear Burner Large - Black

1

297176

Rear Burner Surround-3Bnr - black

1

297184

Rear Burner Surround-4Bnr - black

1

297192

Rear Burner Surround-5Bnr - black

1

297127

Rear Burner Cover-3 Bnr - black

1

297135

Rear Burner Cover-4 Bnr - black

1

297143

Rear Burner Cover-5 bnr - black

54

1

1

1

297200

Rear Burner Valve

55

1

1

1

297119

Rear Burner Collector Box - black

56

1

1

1

293803

Rear Burner S/S Flexline

57

1

1

1

297069

Safety Thermocouple Tube

58

1

1

1

297101

Safety Button Nut

59

1

1

1

297010

Safety Valve Rear Burner

60

1

1

1

297036

Gas Supply Tube - Safety Valve

1

295808

Rear Trim f/Turbo 3B w/RB

1

295816

Rear Trim f/Turbo 4B w/RB

1

297226

Rear Trim f/Turbo 5B w/RB

1

1

297077

3 & 4 R/Bnr F/Thrower Gas Line

1

297085

5 R/Bnr F/Thrower Gas Line

63

1

1

1

1

1

1

297093

Lighting Tube

62

51

52

53

61

44

45

47

33

34

36

40

18

Summary of Contents for CG3TCBN

Page 2: ......

Page 23: ......

Page 24: ...Barbeques Galore z 949 597 2400 z 10 Orchard Road Suite 200 z Lake Forest CA 92630...