19 1/8"

10”

8 1/2"

19 1/8"

10 3/8”

9 1/2”

8 1/2"

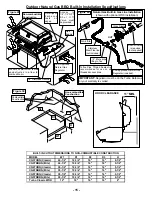

Figure 31

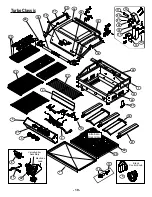

Turbo Classic

Models: XG(3/4/5)TCN

DIM “W1”

clearance required

DIM “W2”

GAS INLET

Figure 33

DIM “W1”

clearance required

DIM “W2”

Turbo Elite

Models: XG(3/4/5)TDN

GAS INLET

Figure 32

1/2” NPT Female Pipe Gas Inlet

8-3/8”

W1

W2

19-1/2”

Turbo Classic Built-in WOK

21-3/4”

Figure 34

1/2” NPT Female Pipe Gas Inlet

8-3/8”

W1

W2

19-1/2”

Turbo Elite Built-in Wok

21-3/4”

Black Porcelain

Control Panel

Stainless Steel

Control Panel

- 16 -

MODEL

W1

W2

CG3TCN

24-1/2" 25-5/8"

CG3TCBRN

24-1/2" 25-5/8"

CG3TDN

24-1/2" 25-3/4"

CG3TDBRN

24-1/2" 25-3/4"

CG4TCN

30-1/2" 31-5/8"

CG4TCBRN

30-1/2" 31-5/8"

CG4TDN

30-1/2" 31-3/4"

CG4TDBRN

30-1/2" 31-3/4"

CG5TCN

38-1/2" 39-3/8"

CG5TCBRN

38-1/2" 39-3/8"

CG5TDN

38-1/2" 39-1/2"

CG5TDBRN

38-1/2" 39-1/2"

Classic & Elite WOK

11-3/4" 13-1/4"

Summary of Contents for CG3TCBN

Page 2: ......

Page 23: ......

Page 24: ...Barbeques Galore z 949 597 2400 z 10 Orchard Road Suite 200 z Lake Forest CA 92630...