51

Item

Qty

(per side)

Part #

Description

1

6

Obtain Locally

LN 3/8 Locknut

2

1

400-354 / 400-941

Left / Right Mounting Bar

3

1

400-943

Light Housing Lid

4

2

Obtain Locally

CB 3/8 x .75 Carriage Bolt

5

1

400-940 / 400-356

Left / Right Housing Light

6

2

Obtain Locally

HB 1/4 x .5 Hex Bolt

7

1

Obtain Locally

LN 7/16 Locknut

8

2

31521

4” Rubber Grommet

9

1

31520

Red Tail Light

10

1

31519

Amber Tail Light

11

1

Obtain Locally

CB 7/16 x 1.5 Carriage Bolt

12

1

400-939 / 400-355

Left / Right Light cover

13

1

Obtain Locally

HB 1/2 x 3 Hex Bolt

14

1

Obtain Locally

LN 1/2 Locknut

15

2

Obtain Locally

HB 5/8 x 2.5 Hex Bolt

16

2

Obtain Locally

LN 5/8 Locknut

17

1

31326

Hydraulic Cylinder

18

4

Obtain Locally

CB 3/8 x 1 Carriage Bolt

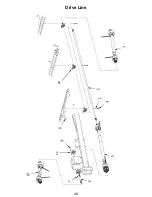

Lights

Summary of Contents for Nitro 450

Page 1: ...Tube Line Manure Spreader Nitro 450 Operator s Manual 31375 Rev 1 3 Nov 11 2014...

Page 23: ...23 Part Lists...

Page 24: ...24 Front Components...

Page 26: ...26 Rear Components...

Page 28: ...28 Beaters 34...

Page 30: ...30 Apron Drive 20...

Page 32: ...32 Apron Runners...

Page 34: ...34 Side Floor Boards...

Page 36: ...36 Single Axle...

Page 38: ...38 Tandem Axle...

Page 40: ...40 Drive Line 11 12...

Page 42: ...42 Endgate Hydraulics...

Page 44: ...44 Chain Drive Hydraulics...

Page 46: ...46 Grease Line Schematic...

Page 48: ...48 Intentionally Blank...

Page 49: ...49 Light Kit TLVLK 450 Available Options...

Page 50: ...50 Lights Right Left...

Page 52: ...52 Light Kit Hydraulics...

Page 54: ...54 Light Kit Electrical Breakdown...

Page 56: ...56...

Page 57: ...57...

Page 58: ......