19

Fluids & Lubricants

1. Grease: Use an SAE multi-purpose

grease with extreme pressure (EP)

performance. Also acceptable is an SAE

multi-purpose lithium base grease.

2. Gearbox Oil: Use an SAE 80W90 gear

oil for all operating conditions.

3. Storing Lubricants: Your machine

can operate at top efficiency only if clean

lubricants are used. Use clean containers

to handle all lubricants. Store them in an

area protected from dust, moisture and

other contaminants.

Greasing your Machine

1. Use only a hand-held grease gun for all

greasing.

2. Wipe grease fitting with a clean cloth

before greasing, to avoid injecting dirt.

3. Replace and repair broken fittings

immediately.

4. If fittings will not take grease, remove

and clean thoroughly. Also clean lubricant

passageway. Replace fitting if necessary.

5. Inject 2-3 pumps on each grease zerk.

Adjusting Apron Chain Tension

1. Occasionally check the apron chain for

any bent or damaged slats. It is important

to straighten or replace any damaged slats

immediately.

2. The apron chain tension should be

checked and adjusted on occasion. If apron

chain has slack, tightening is required:

• To tighten apron chain, loosen the four

bolts on bearing and turn nut until proper

tightness is achieved (both sides) then

tighten 4 bolts on the bearing.

Apron chain tension adjustment of spreader

When adjusting the apron chain tension use

the following procedure.

a) Start on one side and tighten the nut a few

turns.

b) Repeat on opposite side of machine to

evenly tighten chain tension.

c) Repeat this procedure 2-3 times

until moderate chain tension is achieved.

Caution: It is important to ensure nuts on 4

bolts on bearing are tightened after adjusting

apron chain. In the event of the nuts not being

tightened, and the apron chain is reversed,

equipment damage may occur.

Summary of Contents for Nitro 450

Page 1: ...Tube Line Manure Spreader Nitro 450 Operator s Manual 31375 Rev 1 3 Nov 11 2014...

Page 23: ...23 Part Lists...

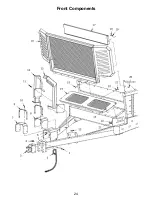

Page 24: ...24 Front Components...

Page 26: ...26 Rear Components...

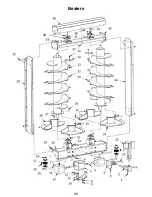

Page 28: ...28 Beaters 34...

Page 30: ...30 Apron Drive 20...

Page 32: ...32 Apron Runners...

Page 34: ...34 Side Floor Boards...

Page 36: ...36 Single Axle...

Page 38: ...38 Tandem Axle...

Page 40: ...40 Drive Line 11 12...

Page 42: ...42 Endgate Hydraulics...

Page 44: ...44 Chain Drive Hydraulics...

Page 46: ...46 Grease Line Schematic...

Page 48: ...48 Intentionally Blank...

Page 49: ...49 Light Kit TLVLK 450 Available Options...

Page 50: ...50 Lights Right Left...

Page 52: ...52 Light Kit Hydraulics...

Page 54: ...54 Light Kit Electrical Breakdown...

Page 56: ...56...

Page 57: ...57...

Page 58: ......