5

e)

Power tools require maintenance. Check power tools for

check it for any damage or use any other undamaged one.

concentricity or jamming of moving parts, any cracks and all

Once the tool bit is checked and attached, stand in

other

plane than the tool bit rotation plane. Set and switch the

other factors affecting the power tool work safety. If any

power tool to its maximum speed (revs), making sure that

damage to the power tool is detected, it should be repaired

the operator and other persons staying in the vicinity are

before use.

Improper power tool maintenance is a reason for many

beyond the zone of rotating tool bit.

Damaged tool bits usually

accidents.

break during this trial period.

f)

Cutting tools should be sharp and clean.

Keeping sharp cutting

e)

Do not leave any loose items, first of all, fixing strings near

edges in good condition reduces the risk of jamming and facilitates

the buffer pad. The fixing strings should be hidden or cut to

operation.

fit.

Any loose, rotating strings may capture your fingers or entangle in

g)

Power tools, equipment, working tools etc. should be used

the object being buffed.

according to this user's manual taking into account

f)

Wear personal protective equipment (PPO). Depending on

operating conditions and the work to be done.

Misusing a

the operation, wear a face mask, eye protection or safety

power tool can result in dangerous situations.

glasses. Where applicable, wear a dust mask, ear protection,

h)

At low temperatures and after a long brakes in operation it is

protective gloves and apron to protect the operator against

recommended to turn the power tool to operate it with no

small particles of abrasive or material machined.

Eye

load for a few minutes to provide proper grease distribution

protection must be capable of catching flying particles generated

inside its driving mechanism.

during various operations. Dust masks and respiratory tract protection

i)

Use soft, damp (cannot be wet) cloth and soap to clean power

should collect dust particles generated during operation. Long-term

tools. Do not use petrol, solvents and other agents that may

exposure to intensive noise can result in hearing loss.

damage your equipment

.

g)

Keep the power cord away from rotating tool bits.

In case of

j)

Power tools can be stored/carried after making sure that all

losing control over the power tool, its power cord can be pulled in, while

moving components are locked and protected against

the palm or the hole hand may get into the rotating tool bit.

release with original devices intended for this purpose.

h)

Immobilize the object to be buffed properly. Make sure its all

k)

Store power tools in a dry, dust and water-protected place.

clamps are properly secured and check for any excessive

l)

Carry your power tool in its original packaging to provide

clearance.

Immobilizing the object in a vice or a clamping device is

protection against mechanical damage.

safer than holding it in your hand.

WARNING! General warnings regarding the use of

i)

Do not switch the power tool on with its disk pointed

power tools.

towards the operator.

j)

Hold the power tool securely with both hands placed behind

Repair

:

the main handle and auxiliary handle and stay in a stable

position.

It is safer to move the power tool with both hands.

k)

Do not carry the power tool when it is operating.

Any

accidental contact of tool bit with clothes may result in pulling it in and

disk contact with operator's body.

l)

Always disconnect the machine from the mains power

during breaks in operation, when replacing buffer pads,

during repairs, cleaning or adjustment. Never put the power

ROTARY BUFFER

tool aside unless its tool bit is completely stopped.

A rotating

Safety tips for using the rotary buffer:

tool bit can come into contact with the surface it has been put down,

a)

This power tool is not intended for polishing.

Using a power

which may result in losing control over the power tool.

tool to perform jobs it is not designed for can be dangerous and may

m)

Clean the power tool venting holes on a regular basis.

Motor

result in injuries.

fan can force dust into the casing, excessive metal dust deposits may

b)

Do not use accessories designed, intended or recommended

result in electric shock.

by the manufacturer for use not specifically with this power

n)

Do not use the power tool near flammable materials.

Sparks

tool.

Even if an accessory can be installed on the power tool, it does not

can cause ignition.

mean it provides safe use or operation.

o)

Do not use tool bits that require liquid coolants.

Using water or

c)

The diameters of buffing disks and flanges must perfectly fit

other liquid coolants may result in electric shock.

the power tool spindle.

Tool bits with openings that do not match

p

)

Never use a tool with damaged cord. Do not touch a

perfectly the spindle diameter, rotate non-uniformly and vibrate

damaged cord; if the cord becomes damaged during work,

intensely, which may result in losing control over the power tool.

take out the plug from the power socket.

Damaged cords

d)

It is absolutely prohibited to use any damaged tool bits.

increase the risk of electric shock.

Before each use check its accessories e.g. buffer pads for

ATTENTION!

If a permanently fixed power cord becomes damaged, it

tears, excessive wear and dirt, buffing disks for cracks, loss of

must be replaced with a special cable or assembly available at the

material or wear. If the power tool or a tool bit is dropped,

manufacturer's or at a specialized repair service po

int.

a)

Power tools can be repaired by competent persons only who

use original spare parts.

It will provide safe operation for the power

tool.

WARNING!

While operating power tools it is necessary to observe basic

work safety rules to avoid fire, electric shock or mechanical

injury.

Summary of Contents for TMA1300K

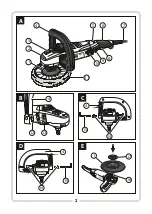

Page 2: ...2 A 1300W 1 2 3 4 5 7 8 9 10 11 B 12 13 C D 14 14 15 4 15 4 E 17 1 16 13 00 W 6 4...

Page 14: ...RCD TMA1300K 14...

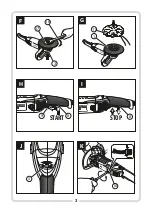

Page 15: ...15 a a...

Page 16: ...16...

Page 19: ...19 n 10 5 7 n K 6 34 03 228 PROFIX...

Page 36: ......