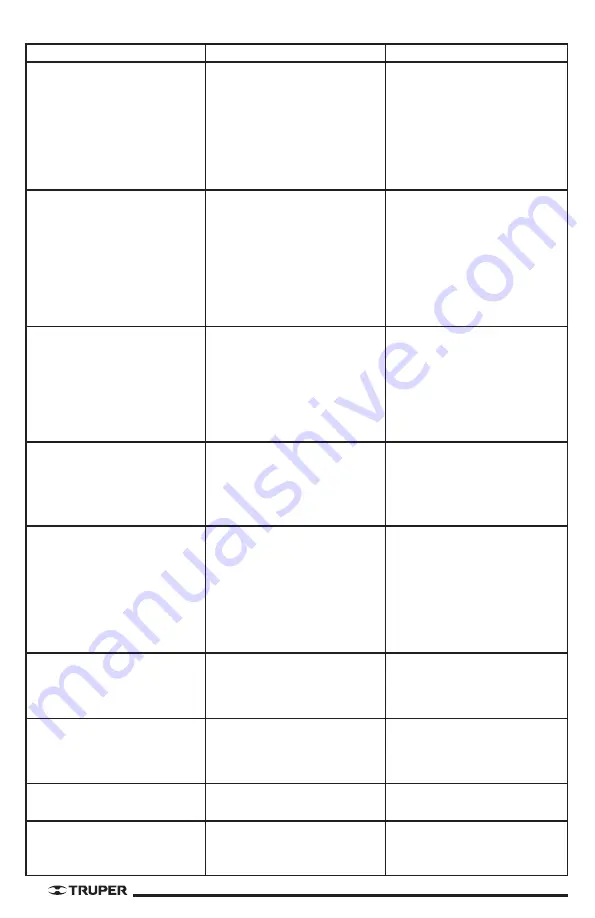

TROUBLESHOOTING

PROBLEM

The compressor is not working.

The motor buzzes but is not running or

runs slowly.

The fuses blow

The circuit breaker is repeatedly

activated.

CAUTION! NEVER USE AN EXTENSION

CABLE WITH THIS UNIT!

The thermal overload protection

repeatedly causes interruptions.

Pressure in the tank drops when the

compressor stops.

Excessive humidity in the discharging

air.

The compressor operates continuously.

The compressor vibrates.

Air output less than normal.

POSSIBLE CAUSE

1. No electricity.

2. Blown fuse in the installation.

3. Air check is open.

4. Thermal switch is activated.

5. Faulty Pressurestat.

1. Voltage drop.

2. Motor winding has a short or is

open.

3. Faulty check valve or pressurestat.

4. Compressed air in the cylinder.

1. Wrong fuse capacity.

2. Faulty check valve or pressurestat.

1. Voltage drop.

2. Blocked air filter.

3. There is no adequate ventilation.

Room temperature is too high.

1. Loose connections (couplings,

pipeline, etc.)

2. Purge key is open.

3. Leaks in the check valve

1. Too much water in the tank.

2. High humidity

3. Admission filter is covered.

1. Faulty pressurestat.

2. Excessive use of air

1. Loose mounting bolts

2. The tank rubber supports are missing

or worn.

1. Open the purge key

2. Dirty admission filter.

3. There is a leak in the connection

SOLUTION

1. Is it connected? Check fuse-circuit

breaker.

2. Replace blown fuse.

3. Restart and determine what caused the

problem.

4. Push the thermal button to restart.

5. Contact a Truper Authorized Service

Center.

1. Check with voltmeter. Minimum

voltage: 115 V˜

2. Contact a Truper Authorized Service

Center.

3. Contact a Truper Authorized Service

Center.

4. Turn the ON / OFF switch into the OFF

position around 15 seconds. Then

turn to the AUTO position.

1. Verify you are using the right fuse. Use

a time-delay fuse. Disconnect other

units using the same circuit or operate

the compressor in an independent

circuit.

2. Contact a Truper Authorized Service

Center.

1. Check with voltmeter. Minimum

voltage: 115 V˜

2. Clean the filter (see Maintenance

section).

3. Move the compressor to a

well-ventilated area.

1. Check to detect air leaks. Use sealing

tape in all the leaking connections.

2. Tighten the purge key

3. Disassemble the unidirectional valve.

Clean and replace. Danger! DO NOT

DISASSEMBLE THE CHECK VALVE

WHEN THERE IS AIR INSIDE THE

TANK. PURGE THE TANK FIRST.

1. Drain the deposit.

2. Move the compressor to a less humid

area. Use a filter in the air pipeline

3. Clean or replace the filter.

1. Contact a Truper Authorized Service

Center.

2. The compressor is not big enough to

satisfy the CFM requirements of the

pneumatic tool.

1. Tighten

2. Replace

1. Pull the safety valve ring to clean the

bolckage.

2. Clean or replace admission filter.

3. Tighten connections.

4

Summary of Contents for COMP-10L

Page 6: ...NOTAS...

Page 14: ...NOTES...