1 3/8”

3/4”

1 1/4”

4”

2 3/4

4”

1 3/8”

1 3/8”

Misaligned Extension

Properly Aligned Extension

8

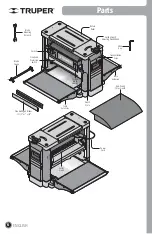

Anti-chip Guard Assembly

• The anti-chip guard is mounted in the rear of the

planer and is fixed with the butterfly nuts.

Adjustments

• The table extensions are factory aligned, however, can

be misaligned with use.

• Adjust the two hex screws (

A

) that act as stoppers for

both extensions (front and rear). Previously, loosen the

safety nuts (

B

).

• Set one straight edge piece through the main table, and

the extension to be adjusted to verify alignment.

Table Extensions Assembly

• Plan a wood piece and measure thickness after cutting.

If the thickness is not even in both sides of the piece, is

because the cutter head and the work piece are not

properly aligned.

• To align, use two identical pieces of hard wood with the

shape and measurements shown in the image (

C

) to level

the cutter head with the table.

• Using care, lean the planer on its rear side.

• Under the main table, loosen the lock (

D

) horizontal

cone gear (

E

).

• Disengage the cone gears and turn the vertical cone gear (

F

) to adjust height in the appropriate side. Turning the

gear one step of a tooth in a counter clockwise direction equals an increase of 0,05” planning thickness.

• After making adjustments, couple and secure the cone gears.

• If necessary, repeat the procedure in the opposite side.

Work Table and Cutter Head Alignment

A

D

B

C

C

F

E

135°

125°

ENGLISH

Summary of Contents for 16240

Page 13: ...13 Notas ESPA OL...

Page 14: ...Notas 14 ESPA OL...

Page 29: ...13 Notes ENGLISH...

Page 30: ...Notes 14 ENGLISH...