5.

Maintenance

Electrical voltage! Risk of fatal injury due to electric shock.

Ø

Remove the plug from the plug socket before undertaking

any maintenance work on the machine.

Risk of injury due to incorrect repair work

Machine does not work properly.

Ø

Maintenance may be carried out by trained specialist techni-

cians only.

Damage to property caused by blunt tools!

Machine overload.

Ø

Check the cutting edge of the cutting tool every hour for

wear or in the event of poor cutting behavior or poor work

result. Sharp cutting tool produces good cutting performance

and protects the machine.

Ø

Change the cutting tool in a timely manner.

Maintenance point

Procedure and interval

Recommended

lubricant

Lubricant

order number

Punch, die and wear parts

Check every hour

-

-

Punch

Regrind/replace as nee-

ded.

-

-

Ventilation slots/grids

Clean as needed

-

-

Die

Change as needed

-

-

Wearing plate

Change as needed

-

-

Punches and die holders

For tool change

Lubricating grease "S1"

0121486

Gearbox and gear head

Every 300 operating

hours, have a trained spe-

cialist relubricate or

replace the lubricating

grease.

Lubricating grease "G1"

0139440

Maintenance positions and maintenance intervals

Tab. 7

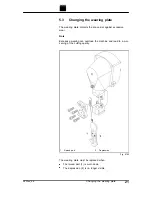

5.1

Replacing the tool

Note

When the punch or die is blunt, or the punch cannot be

reground, the tools must be replaced.

E232en_06

Maintenance

17

DANGER

WARNING

CAUTION