5

7. Installation

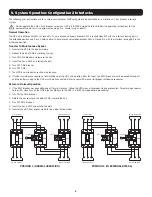

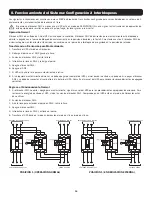

7.2.3 Equipment Connections

Never work on power equipment while it is energized. De-energize equipment and lock off all power to the equipment before working

inside.

The top and bottom panels of the equipment are the recommended designated areas for landing conduit to the equipment. All conduits

must be located to avoid interference with structural members and live bus. A set of drawings for the specific configuration of the equipment

is included inside the equipment. Reference the equipment drawings in

Section 10 Reference Materials

.

All conductors are to be sized for 167°F (75°C) ampacity. When cable is used with temperature ratings above 167°F/75°C, it shall be

sized based on the ampacity of cable rated 167°F (75°C).

The equipment must be grounded with the appropriately sized conductor in compliance with Article 250 of the National Electrical

Code (NEC). The ground conductor should be terminated to the main ground bus bar inside the equipment.

Remove the equipment covers as needed to access the input and output connection points. Where cables enter or exit the equipment or

pass through any metal which has magnetic properties, they shall be arranged so all phase and neutral conductors are grouped together

and pass through the same opening in compliance with Article 300.20 of the National Electrical Code (NEC). When pulling cable into the

equipment, take care not to damage any of the internal components and control wiring. Position the cables inside of the equipment so they

are not subject to physical damage and are not forced permanently against the edges of any metal parts. If any cables are in contact with

sharp edges, place suitable protective material between the cable and the metal edge to protect the cable insulation.

Using the appropriate tools, strip a length of insulation from the end of the cable sufficient to fit into the full length of the mechanical lug

for the designated connection point. If using aluminum conductors, apply an appropriate antioxidant compound to the bare aluminum.

Insert the bare conductor into the lug so the bare conductor fills the full length of the mechanical lug body. Tighten the set screw on the

mechanical lug and torque to the values indicated on the Torque Values Label located on the equipment.

Reference the Equipment Schematic Drawing for information on the required connections between the Maintenance Bypass Panel, the UPS

and the critical load.

7.2.4 Pre-Energizing Inspection

Inspection and maintenance should only be performed on equipment that has been de-energized and electrically isolated so that no

accidental contact can be made with energized parts.

The top and bottom panels of the equipment are the recommended designated areas for landing conduit to the equipment. All conduits

must be located to avoid interference with structural members and live bus. A set of drawings for the specific configuration of the equipment

is included inside the equipment. Reference the equipment drawings in

Section 10 Reference Materials

.

Before energizing the equipment, it must be thoroughly inspected.

1. Remove any foreign materials from inside of the equipment including tools, scraps of wire or other debris.

2. Visually inspect the equipment for any damage that may have occurred during the installation process. Be sure to inspect all insulators,

busbars and other conductors. Do not energize if any damage is found!

3. Verify cable phase orientation at all connection points.

4. Verify all field cable connections are properly torqued.

5. Manually operate all circuit breakers to verify proper operation.

6. Verify the circuit breaker trip unit adjustments are set per the end user requirements.

7. Verify equipment ground connections are properly terminated.

8. Review the Kirk Key interlock operating sequence and confirm the Kirk Key interlocks are performing properly.

9. Verify all covers are installed.

7.2.5 Energizing

Hazardous voltages in electrical equipment can cause severe injury or death!

Only qualified persons should attempt to install or service this equipment. A qualified person is one who has skills and knowledge

related to the construction and operation of electrical equipment and installations and has received safety training on the hazards

involved.

Ensure maximum continuous loads do not exceed 80% of the overcurrent protective device (circuit breaker and fuses) ratings at

nominal input voltage of 208V/120V AC employed in other than motor circuits, except for those circuits employing circuit breakers

marked as suitable for continuous operation at 100% of their ratings.

Extreme hazards can exist when energizing electrical equipment. Take all precautions necessary to protect people and property when

energizing this equipment. Before energizing the equipment, open/turn off all circuit breakers and verify the Kirk Key interlocks are in the

correct state to allow for proper startup. Refer to the UPS manual for proper startup procedures.