42

ADJUST OIL BURNER BEFORE STARTING. (AFG)

1.

NOTICE

These instructions are for Beckett AFG. For other burners, refer

to the manufacturer’s manual. The nozzle and air setings are

given in Table 14. For direct vent installation guide, see Direct

Vent Addendum.

Refer to burner manufacturer’s manual for details.

A.

Check burner air band, air shutter and head setting (if

B.

equipped), readjust if necessary, see

Burner Settings

section

of this manual.

Open all oil line valves.

C.

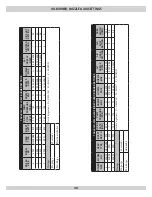

Table 11: L7248A Controller

Operating Sequence

Action

System Response

Thermostat calls

for heat.

Circulator starts. Boiler temperature

is checked. Burner starts.

Boiler exceeds

the high limit.

Burner is turned off. Burner restarts

when the water temperature drops

below the high limit setting minus the

differential.

Thermostat is

satisfied.

Circulator and burner turned off.

Burner (AFG) post-purge is 15

Error

Condition

If an error condition is detected, all

outputs are shut down. Burner is

off. Control continues to function

and restarts when error is corrected.

During the error check sequence, the

system checks for drift in the sensor

and corrosion in the connections.

Attach a plastic hose to fuel pump vent fitting and provide a

D.

pan to catch the oil.

START OIL BURNER

2.

Open vent fitting on fuel pump. (See

A.

Pump Priming Cycle,

4.B.II)

Press red reset button on front of oil primary cover, hold for 30

B.

seconds and release to reset primary control, if required.

Turn on burner service switch and allow burner to run until oil

C.

flows from vent fitting in a SOLID stream without air bubbles

for approximately 10 seconds.

Close vent fitting and burner flame should start immediately

D.

after pre-purge is completed. Pre-purge prevents burner flame

until 15 seconds has elapsed after initial power is applied to

burner. During pre-purge the motor and igniter will oper-

ate but the oil valve will remain closed. (Refer to Oil Primary

Control Instructions,)

Adjust oil pressure.

E.

When checking a fuel unit’s operating pressure, a reliable pres-

I.

sure gauge may be installed in either the bleeder port or the

nozzle port.

Locate oil pressure adjusting screw and turn screw to obtain

II.

proper pump pressure, refer to

Burner Settings

section of

this manual.

To check the cut-off pressure, deadhead a reliable pressure

III.

gauge onto the copper connector tube attached to the nozzle

port. Run the burner for a short period of time. Shut the

burner off. The pressure should drop and hold.

Remove the gauge and install bleeder port and/or reconnect

IV.

the nozzle port line.

ADJUST OIL BURNER WHILE OPERATING.

3.

Adjust Draft Regulator for a breech draft of -0.5 (preferred) to

A.

0 inches water column after chimney has reached operating

temperature and while burner is running. (At least five min-

utes) See

Burner Settings

section of this manual for details.

Readjust the air band on burner while the breach draft is -0.5

B.

to 0 inches water column (WC). Use a smoke tester and adjust

air for minimum smoke (not to exceed a trace) with a mini-

mum of excess air. Make final check using suitable instru-

mentation to obtain a CO

2

of 11.5 to 13%. These settings will

assure a safe and efficient operating condition. If the flame

appears stringy instead of solid fire, try another nozzle of the

same type. Flame should be solid and compact. After all adjust-

ments are made, recheck for a draft in the breach. See

Burner

Settings

section of this manual.

Re-adjust the head setting only if necessary.

C.

The switching action in the L7248A control has one setting, the

high limit. The switching relay is controlled by the low voltage room

thermostat. On a call for heat, the relay contacts close to complete

the line voltage circulator circuit and also the burner circuit if the

boiler water temperature is below the high limit setting. The high

limit switch shuts off the burner if boiler water temperature exceeds

the high limit setting. The circulator will continue to operate as long

as the thermostat is calling for heat. The high limit automatically

rests after the water temperature drops below the set point minus the

differential.

OPerATiNg THe BOiLer - SYSTeM STArT-UP