Revision: 0

FlexxPump4 D

User Manual

46

EN-

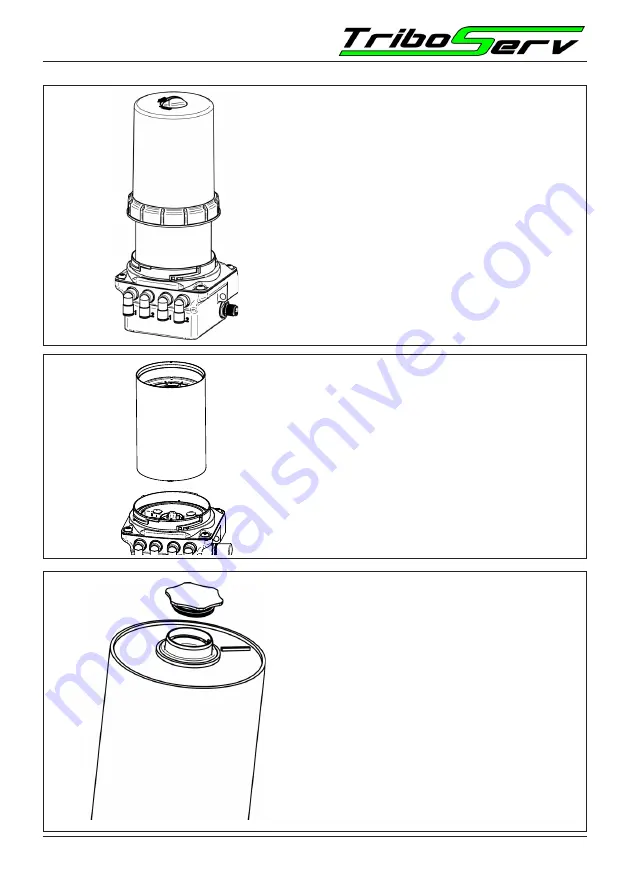

1. Remove the housing from the power unit

of the FP4 D.

Separate the housing from the power unit

by turning the retaining ring counterclock-

wise.

Make sure that no dirt, water or foreign

bodies enters the lubricant inlet.

3. Remove the cartridge cap from the new

cartridge.

Turn the cap of the lubricant cartridge

counterclockwise and pull it off.

Pay attention to cleanliness when

carrying out the work. Be sure to prevent

dirt, liquids and foreign bodies from entering

the cartridge.

2. Remove the empty cartridge.

Turn the empty cartridge counterclockwi-

se and pull it off.

Pay attention to cleanliness when

carrying out the work. Be sure to prevent

dirt, liquids and foreign bodies from entering

the grease inlet.