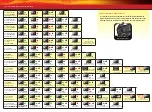

34 • DRAG SLASH

TQ

i

ADVANCED TUNING GUIDE

Set Multi-Function

knob for STEERING

SENSITIVITY (Expo)

Press/hold MENU

green LED blinks

Press SET

red LED blinks

x

8

Press SET to confirm

green LED blinks (x8)

Press/hold MENU

returns to driving mode

Set Multi-Function

knob for THROTTLE

SENSITIVITY (Expo)

Press/hold MENU

green LED blinks

Press SET

red LED blinks

x

2

Press MENU to confirm

red LED blinks (x2)

x

8

Press SET to select

green LED blinks (x8)

Press/hold MENU

returns to driving mode

Set Multi-Function

knob for STEERING

DUAL-RATE (%)

Press/hold MENU

green LED blinks

Press SET

red LED blinks

x

3

Press MENU twice

red LED blinks (x3)

x

8

Press SET to select

green LED blinks (x8)

Press/hold MENU

returns to driving mode

Set Multi-Function

knob for BRAKING

PERCENTAGE (%)

Press/hold MENU

green LED blinks

Press SET

red LED blinks

x

4

Press MENU 3 times

red LED blinks (x4)

x

8

Press SET to select

green LED blinks (x8)

Press/hold MENU

returns to driving mode

Set Multi-Function

knob for

THROTTLE TRIM

Press/hold MENU

green LED blinks

Press SET

red LED blinks

x

5

Press MENU 4 times

red LED blinks (x5)

x

8

Press SET to select

green LED blinks (x8)

Press/hold MENU

returns to driving mode

Adjust the Multi-

Function knob until the

LED turns solid green.

To LOCK the

Multi-Function knob

Press/hold MENU

green LED blinks

Press SET

red LED blinks

x

6

Press MENU 5 times

red LED blinks (x6)

x

8

Press SET to lock

green LED blinks (x8)

Press/hold MENU

returns to driving mode

To REVERSE

the direction of

STEERING servo

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

Press SET

red LED blinks

x

8

Press SET

to reverse

servo direction

Press/hold MENU

returns to driving mode

To set the SUB TRIM

of the STEERING

servo

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

Press SET

red LED blinks

x

2

Press MENU

red LED blinks (x2)

Use Multi-Function

knob

to set neutral

x

8

Press SET

to save position

Press/hold MENU

returns to driving mode

To set the END

POINTS of the

STEERING servo

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

Press SET

red LED blinks

x

3

Press MENU twice

red LED blinks (x3)

Turn steering

wheel

to desired max

left and right travel

x

8

Press SET

to save each position

Turn steering wheel

to test settings

IF END POINTS

ARE OK:

Press/hold MENU

returns to driving mode

IF END POINTS

NEED TO BE

CHANGED:

Press SET

and repeat steps 6-8

To reset the END

POINTS of STEERING

servo to defaults

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

Press SET

red LED blinks

x

4

Press MENU 3 times

red LED blinks (x4)

x

8

Press SET

to reset end points

Press/hold MENU

returns to driving mode

To REVERSE

the direction of

THROTTLE servo

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

red LED blinks

x

8

Press SET

to reverse

servo direction

Press/hold MENU

returns to driving mode

To set the SUB TRIM

of the THROTTLE

servo

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

red LED blinks

x

2

Press MENU

red LED blinks (x2)

Use Multi-Function

knob

to set neutral

x

8

Press SET

to save position

Press/hold MENU

returns to driving mode

To set the END

POINTS of the

THROTTLE servo

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

red LED blinks

x

3

Press MENU twice

red LED blinks (x3)

Use throttle

trigger

to set desired

max throttle or brake

Press SET

to save

Use trigger to test

IF END POINTS

ARE OK:

Press/hold MENU

returns to driving mode

IF END POINTS

NEED TO BE

CHANGED:

Press SET

and repeat steps 7-9

To reset the END

POINTS of THROTTLE

servo to defaults

Press/hold MENU

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

green LED blinks

x

2

Press MENU

green LED blinks (x2)

Press SET

red LED blinks

x

4

Press MENU 3 times

red LED blinks (x4)

x

8

Press SET

green LED blinks (x8)

Press/hold MENU

returns to driving mode

MENU TREE FORMULAS

To select functions and make adjustments to the TQi transmitter without

referencing the Menu Tree, turn your transmitter on, find the function in the

left column you wish to adjust, and simply follow the corresponding steps.

Always turn your

transmitter on first.

1

1