16

Well Water

Systems

Application

Considerations

7

6

2

3

4

5

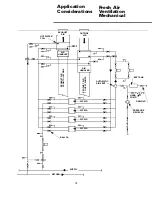

Figure 11: Well water installation

1

9

8

Su

pp

ly

Ov

erf

low

Re

tur

n

General

A well water application involves an

open loop water supply. The water

is drawn from an open well or pond

into the unit. A straining device is

required with this application.

Similar to the closed loop design,

an open water supply usually

remains at a constant temperature

year round utilizing maximum

efficiency in unit design.

See Figure 11 for open well water

installation.

Well Water

Application

Ball valves should be installed

in the supply and return lines

for unit isolation and unit water

flow rate balancing (if auto-

matic flow device is not

selected). This connection,

along with hoses, are also rec-

ommended for backflushing

and chemical cleaning of the

evaporator and the condenser.

Flexible hoses may be used to

connect the water supply and

return lines to the water inlets

and outlets. These hoses

reduce possible vibration

between the unit and the rigid

system.

Note: Hoses and or pipes

should be braided stainless

steel, and sized suitable for the

system’s water pressure and

flow rate.

Load side connections are

used to supply the terminal

device.

The sound attenuation pad

should be slightly oversized for

the unit. This field supplied

product is recommended for

sound absorption of unit.

The low voltage control con-

nection provided on the unit is

large enough for attaching con-

duit.

The expansion tank should be

sized to maintain pressure on

the system.

The line voltage disconnect

should be installed for branch

circuit protection. The unit is

supplied with an opening for

attaching conduit.

The water regulating valve

assembly is used to maintain

refrigerant pressure in refriger-

ant circuit as the entering water

temperature varies or is cooler

than ideal.

Schrader connections are

factory installed for ease of

attaching the water regulating

valve assembly.