14

The ZN510 controller receives the

fan mode from either a wired zone

sensor or as a communicated valve.

When neither a zone sensor nor

communicated fan mode are

present, the ZN510 controller will

default unit operation to

AUTO

.

Note:

z

A building automation system

can also generate a fan mode

request and communicate this

request to the controller.

z

If the ZN510 controller does not

receive a hardwired or commu-

nicated request for the fan

mode, the unit recognizes the

fan input as

AUTO

and the fan

operates according to the

default configuration.

Fan Off Delay

When the heating output is

controlled off, the ZN510

automatically runs the fan

ON

for an

additional 30 seconds to give the fan

time to blow off any residual heat.

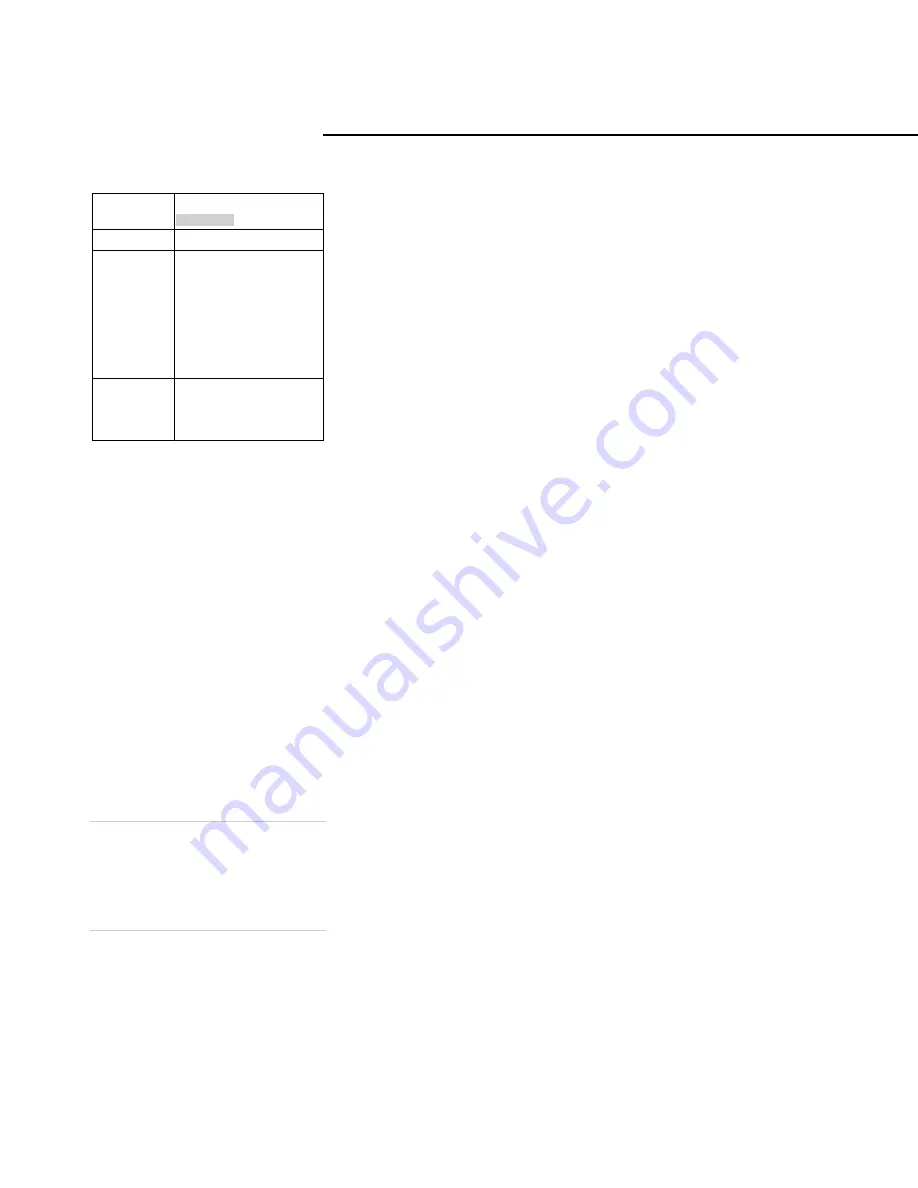

Possible

Fan Modes

Heat Pump

(1-speed)

OFF

Fan Off

AUTO

Continuous: (Field

Modified)

z

In occupied mode, the

fan runs continuously.

In unoccupied mode,

the fan cycles

OFF

when no heating or

cooling is required.

AUTO

Cycling: (Factory Default)

z

The fan cycles

ON

and

OFF

with compressor

operation.

Unit Operation

Leaving Water Temperature

ZN510 uses analog input 1 (AI 1) as

the leaving water temperature input

for use with a thermistor. This input

(AI 1) is automatically assigned as a

leaving water temperature input. As

explained in the binary input

section, the leaving water

temperature input protects the heat

exchanger (circuit 1) from low

temperatures. The second heat

exchanger, present in units with two

compressors is protected with a

binary low temperature detection

device. Based on the application of

the unit, circuit operation is

terminated when the leaving water

temperature falls below 35 F or

20 F. This is set when the unit is

ordered.

The ZN510 controller compares the

measured leaving water

temperature to the leaving water

temperature low limit value to

determine a fault condition. When

the measured leaving water

temperature is less than the leaving

water temperature low limit, the

controller generates a Low Temp

Detect diagnostic. If the Leaving

Water Temp Sensor fails to open or

close the controller generates a

Leaving Water Temp Failure

diagnostic. This disables unit

operation.

Note:

A low temperature detection failure

diagnostic for compressor 1 may

require you to manually reset the

unit to restore compressor opera-

tion.

Similarly, the ZN510 controller uses

a binary low temperature detection

device (fixed low limit trip point) to

lock-out circuit 2 when a fault condi-

tion is detected.

See the Diagnostics section on page

28 for information about the

automatic diagnostic reset function.

Filter Maintenance Timer

The controller’s filter maintenance

timer is based on the unit fan’s

cumulative run hours. The controller

compares the fan run time against

an adjustable fan run hours limit

(maintenance required setpoint

time, stored in the controller) and

recommends unit maintenance (i.e.

changing the filter).

Use Rover or BAS system to edit the

maintenance required setpoint time.

Once the setpoint limit is exceeded

the controller generates a filter

maintenance timer diagnostic.

When the maintenance required

setpoint time is zero, the controller

disables the diagnostic feature.

Discharge Air Temperature

Analog input 2 (AI 2) is used as the

discharge air temperature input for

use with a 10,000 ohm thermistor.

Typical factory placement of the

thermistor is at the discharge area of

the unit. The discharge air

temperature sensor does not affect

unit operation. The measured

temperature is for information only

to be read by the building

automation system or for

troubleshooting unit operation with

Rover.

Once a valid discharge air

temperature signal has been

established by the thermistor or

communicated and the value is no

longer present, the controller

generates a discharge air

temperature failure diagnostic. This

will not disable unit operation. If the

sensor returns with a valid

temperature, the diagnostic

automatically clears