20

CTV-SVX06J-EN

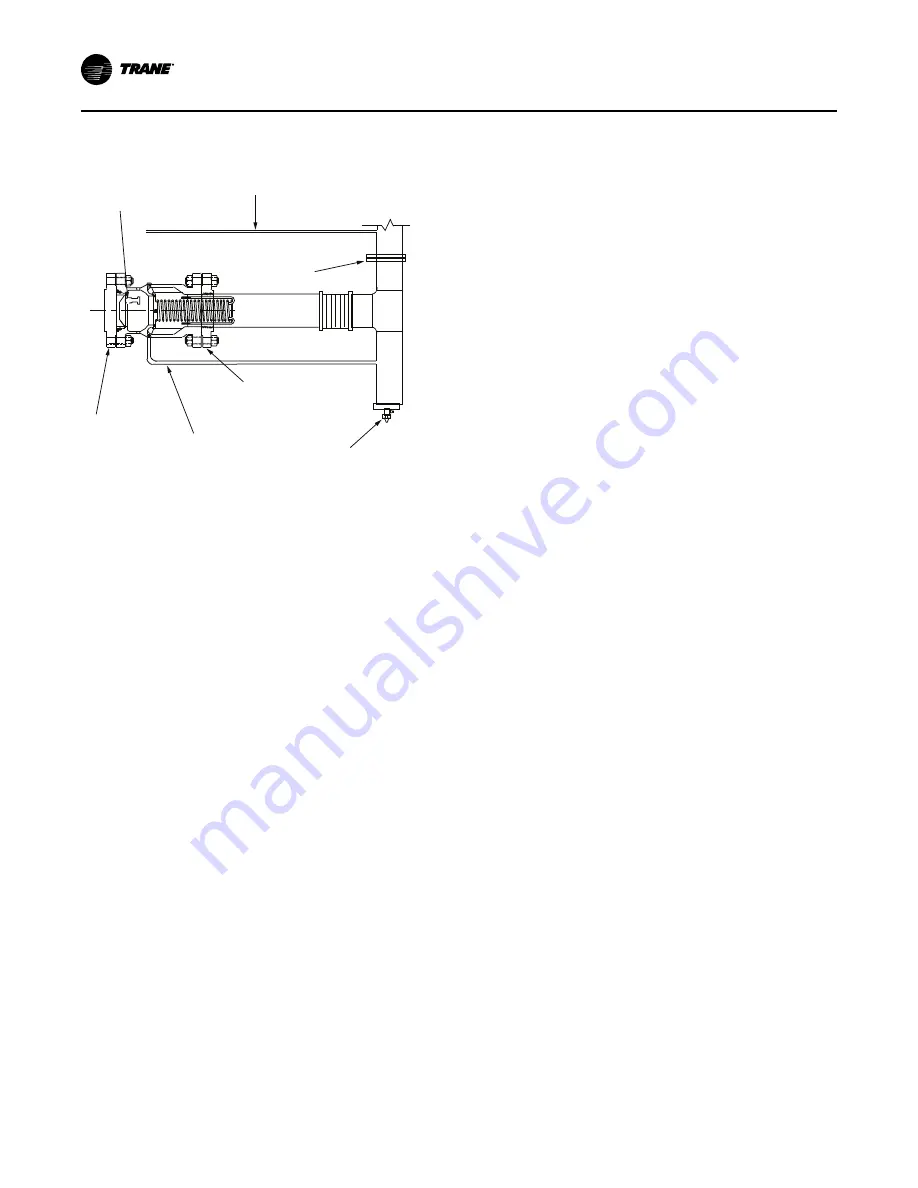

Figure 19.

RuptureGuard external vent line and drip

leg (not provided)

Metal

RuptureGuard

disk

Purge

exhaust

Flange

Vent to

outdoors

Flange

Drain

line

Chiller

flange

Drain

valve

Drip

leg

Important:

The purge exhaust line MUST be connected to the

downstream side piping to vent purge exhaust out the vent line

to the outdoors; it may need to be extended to the drip leg.

Field-acquired tubing may be required to extend to the

field-supplied vent piping, depending on distance. Do NOT

create a U-trap in the purge exhaust line; this line MUST be

sloped from purge (highest point toward field-supplied piping,

lower point toward connection) to allow proper draining of any

condensation.

N

No

otte

ess::

•

Use Loctite

®

242 or Loctite

®

277 on all

threaded joints on chillers charged with

refrigerant; use of other pipe thread sealants

is NOT recommended. Ensure all threaded

pipe joints are properly cleaned and

prepared before assembly. An alternative to

the use of Loctite

®

is to thread and weld the

inlet adapter to the pipe. Care must be taken

to ensure that the flange mating surface

remains flat. Do NOT weld on the Inlet

Adapter flange while connected to the

RuptureGuard

™

.

•

The drip leg is REQUIRED. The drip leg

should be a minimum of 1 gal (3.8 L)

capacity and must be drained periodically

for proper chiller purge operation.

Install Pressure Gauge and

Excess Flow Valve

1. Screw the 1/4-in. (6.4 mm) NPT pressure gauge and

1/4-in. (6.4 mm) NPT excess flow valve into the

threaded ports located in the disk-valve interspace

of the valve body.

N

No

otte

e:: The excess flow valve must be installed to

maintain the downstream side of the rupture

disk at atmospheric pressure to assure proper

operating conditions for the disk. Mount the

excess flow valve as close to horizontal as

possible (see ). Do NOT use vertical ports for

the excess flow valve.

2. If required, screw the 1/4-in. (6.4 mm) NPT pressure

switch in the remaining threaded port.

N

No

otte

e:: Use Loctite

®

242 or Loctite

®

277 on ALL

threaded joints on chillers charged with

refrigerant; use of other pipe thread sealants

is NOT recommended. Ensure all threaded

pipe joints are properly cleaned and prepared

before assembly. An alternative to the use of

Loctite

®

is to thread and weld the Inlet

Adapter to the pipe. Care must be taken to

ensure that the flange mating surface

remains flat. Do NOT weld on the Inlet

Adapter flange while connected to the

RuptureGuard

™

.

Pressure Switch

A calibrated pressure switch, used to signal a disk

rupture, comes standard with each RuptureGuard

™

(installation is optional). When a disk ruptures, the

pressure inside the valve holder section increases to

the chiller pressure. The increased pressure changes

the position of the switch’s SPDT contacts. See

for detailed switch ratings.

The use of the binary output signal from the switch is

specific to each application. Some typical ways the

switch output can be used are:

•

provide the switching action to activate a local or

remote audible or visual alarm.

•

provide an alarm contact closure to a building

management system, such as Tracer

™

.

•

wired in series with other safety controls to shut

down pumps, boilers or other ancillary system

components that may be contributing to the high

pressure condition.

Leak Test

1. Leak test the RuptureGuard

™

installation using dry

nitrogen and soap; pressure test the

RuptureGuard

™

at 5 psig (34.5 kPaG).

2. Finalize with 5 psig (34.5 kPaG) dry nitrogen until

chiller commissioning.

Installation Complete Checklist

☐

All parts received; if not, contact supplier using

telephone number listed in the packing lists.

☐

For a new chiller, release the nitrogen holding

charge from the chiller to the outdoors.