ONLY DIPSWITCH

1 ON **

ONLY DIPSWITCH

2 ON

ONLY DIPSWITCH

3 ON

LOWER *

MIDDLE

UPPER

55

194

195

199

60

208

210

215

65

224

227

232

70

242

246

250

75

260

265

270

80

280

286

291

85

301

308

313

90

324

331

337

95

348

356

362

100

373

382

388

105

399

409

416

110

427

438

445

115

456

467

475

120

486

498

507

125

517

531

540

** With AM7 or AM8: Dip switch 1 = 10° of subcooling at 95° ambient

PRINTED FROM D155859P02 REV 4

3 TON HP R410A REFRIGERANT CHARGING CHART

* Data is based on 11.5° of subcooling at a 95° ambient

LIQUID GAGE PRESSURE (PSIG)

Liquid

Temp (°F)

3

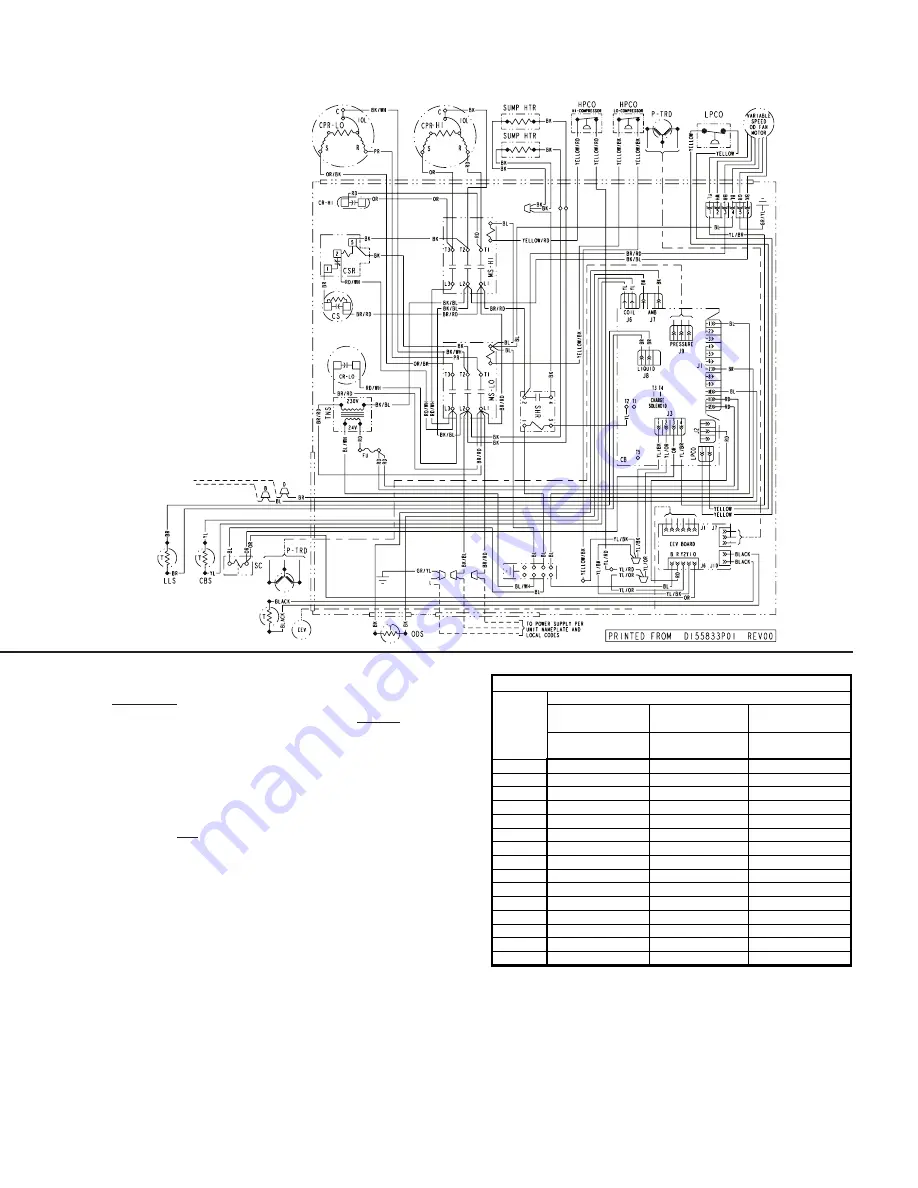

WIRING DIAGRAM

MANUAL CHARGING OR CHARGE ASSIST

TM

METHOD IN

COOLING

BETWEEN 55°F AND 120°F OD AMBIENT

It is recommended to install manufacturer approved matched indoor and

outdoor systems.

All approved split systems are AHRI rated with only TXV indoor systems.

The benefits of installing approved indoor and outdoor split systems are

maxi mum efficiency, optimum performance and the best overall system

reliability. The following charging methods are therefore prescribed for

matched systems with indoor TXVs.

1. Subcooling using the R-410A Refrigerant Charging Chart (in the cooling

mode) is the only recommended method of charging between 55°F and

120°F ambient temperatures.

2. When charging for ambient temperatures above 120°F, charge to 10°

subcooling. It is important to return when outdoor ambient temperature

is between 55°F and 120°F to verify system charge per these instruc-

tions.

3. For best results – the indoor temperature should be kept between 70°F

to 80°F. Add system heat if needed.

4. At startup, or whenever charge is removed or added, the system must

be operated for a minimum twenty (20) minutes to stabilize before

accurate measurements can be made. (Feature of Charge Assist™)

5. Measure Liquid Line Temperature and Refrigerant Pressure at service

valves. (Not required with Charge Assist.™)

6. Determine total refrigerant line length, and height (lift) if indoor section is above the condenser. Set dip switches on Charge Assist™ board as

indicated in the Subcool Charging Corrections Table on page 2 .

7. Locate your liquid line temperature in the left column of the table, and the intersecting liquid line gage pressure under the DIPSWITCH selection

column. Add refrigerant to raise the pressure to match the table, or remove refrigerant to lower the pressure. For manual charging, always wait twen-

ty (20) minutes for the system conditions to stabilize before adjusting charge again. (Not required with Charge Assist.™)

8. Charge Assist port is designed for liquid refrigerant charging.

9. When system is correctly charged, you can refer to System Pressure Curves (on page 8) to verify typical performance.