28

4

UNT-PRC002-GB

Technical Data

FWD

08

12

20

30

45

Power supply

(V/Ph/Hz)

230/1/50

Capacities

Cooling capacity on water (1)

(kW)

5,2

8,3

15

18,8

30,1

Heating capacity on water (2)

(kW)

6,3

11,9

18,9

20,9

38,2

Fan motor

(type)

2 x direct drive centrifugal

Fan power input (3)

(kW)

0,23

0,46

0,65

1,04

1,51

Current amps (3)

(A)

1,1

2,2

3,1

4,7

5,5

Start-up amps

(A)

3,2

5,5

9,3

14,1

16,5

Air flow

minimum

(m

3

/h)

490

980

1400

1800

2700

nominal

(m

3

/h)

820

1650

2300

3000

4500

maximum

(m

3

/h)

980

1970

2600

3600

5400

Main coil

Water entering/leaving connections

(type)

ISO R7 rotating female

(Dia)

3/4"

3/4"

1 1/2"

1 1/2"

1 1/2"

Electric heater (accessory for blower only)

Electric power supply

(V/Ph/Hz)

230/1/50

230/1/50 or 400/3/50

400/3/50

400/3/50

400/3/50

Heating capacity

(kW)

2/4

8

10

12

12

Hot water coil (accessory for blower only)

Heating capacity (4)

(kW)

6,3

12

17,4

22,4

34,5

G2 filter (filter box accessory)

Quantity

2

2

2

2

2

Dimensions ( LxWxth)

(mm)

386x221x8

486x271x8

586x321x8

586*421*8

586*621*8

G4 filter (filter box accessory)

Quantity

-

2

2

2

2

Dimensions ( LxWxth)

(mm)

-

486x264x48

586x314x48

586*414*48

586*614*48

Condensate pump (accessory)

(type)

Centrifugal

Water flow - lift height

(l/h - mm)

24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5)

(dB(A))

36/40/43

38/41/44

46/50/53

47/52/57

47/52/58

Sound power level (5)

(dB(A))

46/50/53

48/51/54

56/60/63

57/62/67

57/62/68

Unit dimensions

Width x Depth

(mm)

890 x 600

1090 x 710

1290 x 820

1290 x 970

1290 x 1090

Height

(mm)

250

300

350

450

650

Shipped unit dimensions

Width x Depth

(mm)

933 x 644

1133 x 754

1333 x 864

1333 x 1008

1333*1133

Height

(mm)

260

310

360

460

660

Weight

(kg)

32

46

61

76

118

Colour

galvanised steel

Recommended fuse size

Unit alone (aM/gI)

(A)

8/16

8/16

8/16

8/25

8/25

Unit with electric heater (gI)

(A)

16 (2kW),25 (4kW)

40 (230V),3*16 (400V)

3*20

3*25

3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

AH-SVX03C-GB

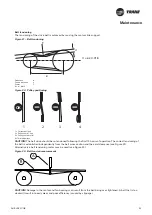

Duct static pressure sensor

The duct static pressure sensor should be mounted in the supply ductwork, approximately two thirds of the distance

from the fan to the end of the longest run of ductwork. The sensor requires two pairs of screened cable to the control

panel.

One pair supplies power to the device and the other is the pressure signal from the device to the controller.

Outside temperature sensor

The outside temperature sensor should be mounted on a Northfacing wall. It requires a single pair of screened wires.

The sensor can be factory mounted in the fresh air inlet. Other items are supplied loose on a project specific basis

and data sheets are available for these items.

Mains connection

Mains connections are normally made through the bottom of the control panel. All the cables should be suitably

arranged so as not to put excessive strain on the terminals. They should be fitted with suitable glands to prevent

water ingress.

Reconnection of sectionalized units

If the unit is supplied in sections, the internal control wiring will have been disconnected in the factory between

sections using break point connectors and the cables will be marked with identifiers. Site reconnection is to be done

by a contractor.

Wiring requirements

Running sensor wires in the same conduit or bundle with any AC power wires other than 24VAC may cause a

malfunction. With on site fitted items, the screened wire should be covered with insulation tape at the sensor

terminal box. Site mounted sensor cables should be Belden 8760 for 2 core devices and Belden 9402 for 4 core

cables.

Fire signal (option)

The AHU unit maybe interfaced to a fire alarm shut down by connecting a normally closed contact to the designated

terminals. If this is not required, the fire contacts are replaced by a link. Remote fireman's override switches can be

connected to allow operation of the extract fan after a fire alarm has been actuated. Where a mixing box is fitted, the

exhaust air damper will be driven to the fully open position while the mixed air and fresh air dampers are driven

closed.

Override contacts can be connected to the designated terminals where this option has been ordered.

Filter section

Depending on the order, a common or an individual filter switch is provided to indicate when the filter section

differential pressure is excessive. The filters may need to be changed.

Frost protection thermostat

In the event that the coil air on temperature drops below 5°C, a thermostat is provided to switch off the supply fan on

units with water coils. It is a hard-wired form of protection and can only be monitored by the controller. This prevents

hot water coils from freezing and would typically operate in cold weather if the hot water coil supply has failed.

Fan section

A pressure differential switch is provided across each fan to provide a proof of airflow indication. All fan / motor are

belt and pulley driven.

Frequency of inspections

It is recommended to inspect all end devices supplied with the unit for correct operation and calibration on an annual

basis.

Recommended spare parts list

If required, a list of recommended components to be kept on site can be provided.

Factory engineered controls