23

11

UNT-PRC002-GB

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan

Power level in dB(A), per Hz frequency band

Overall power

Unit

speed

125

250

500

1000

2000

4000

8000

dB(A)

1

55

50

42

37

37

31

30

46

FWD 08

2

57

54

47

40

30

38

40

50

3

58

57

50

42

32

40

43

53

1

57

51

45

42

34

33

28

48

FWD 10

2

58

54

48

45

38

39

35

51

3

60

58

50

48

40

42

39

54

1

57

51

45

42

34

33

28

48

FWD 12

2

58

54

48

45

38

39

35

51

3

60

58

50

48

40

42

39

54

1

56

62

50

48

39

38

36

56

FWD 14

2

61

66

55

53

47

46

45

60

3

63

69

58

56

50

50

49

63

1

57

63

51

49

40

39

37

57

FWD 20

2

61

66

55

53

47

46

45

60

3

63

69

58

56

50

50

49

63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan

Power level in dB(A), per Hz frequency band

Overall power

Unit

speed

125

250

500

1000

2000

4000

8000

dB(A)

1

56

55

55

53

46

45

42

57

FWD 08

2

63

62

60

60

53

53

53

64

3

66

65

63

62

56

55

57

67

1

62

58

55

58

51

48

44

61

FWD 10

2

66

63

60

62

56

55

52

66

3

70

67

63

65

59

59

57

69

1

62

58

55

58

51

48

44

61

FWD 12

2

66

63

60

62

56

55

52

66

3

70

67

63

65

59

59

57

69

1

66

65

65

65

57

50

46

68

FWD 14

2

73

72

69

71

64

59

57

74

3

78

76

73

75

69

64

63

78

1

68

72

64

64

56

52

50

69

FWD 20

2

76

76

68

71

65

61

61

75

3

78

79

71

74

69

66

66

78

AH-SVX03C-GB

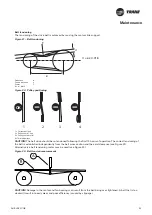

Vibration isolators

Check that vibration isolators are free to operate and that there is no contact existing between the fan/motor

chassis and the support.

Frequency inverter

1. The VFD must be compatible with HVAC applications, such as fans with quadratic torque.

2. The electric power output of the VFD shall be compatible with the nominal power of the motor.

3. The VFD shall be compatible with its environment (IP rate, type of ventilation, ambient temperature,

electromagnetic environment…)

4. All recommendations indicated in the Installation/Operation/Maintenance manual of the VFD manufacturer must

be respected.

5. The VFD comes with default values which may have to be fine- tuned during commissioning.

CAUTION!

In some cases, mechanical issues my affect the fan or motor, and may be caused by the inverter settings (vibration,

excessive noise, lower efficiencies, motor overheating…). If the inverter is removed and the mechanical issues do

not persist, the inverter settings must be reconfigured. Inverter settings to verify can include: attenuated resonance,

quadratic torque, frequency regulation, etc.

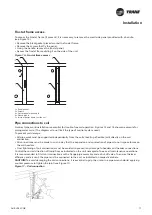

Unit connections

All electrical, water, and duct work connections of the unit must be completed by a qualified person.

Check that electrical connections comply with the wiring diagram and that the thermal protection is operational.

Completely stress-free connections are essential.

The pipe work of the coils should be arranged to facilitate easy removal of the coil for maintenance purposes.

Coils

Check that the coil connections and valves are not leaking. If there are leaks, rectify the problem.

Cooling coil sections are fitted with condensate drains. Check that these are properly fitted to allow draining and

avoid air suction and water carry-over.

Water coil filling

In general, heating and cooling coils are filled with water and standard additives to protect against freezing and

corrosion:

• open the air vent

• slightly open the water supply valve so that the heater battery fills slowly. This avoids thermal stress

• as soon as the heater coil is full, close the air vent

• open the water valve fully and switch on the fan

• finally, the entire piping system must be completely vented.

Steam coil filling

• Open gradually the air vent and drain valve on the condensate drain

• Slightly open the steam valve until steam penetrates through the condensate drain valve and air vent

• Close the condensate drain valve and air vent and open the steam valve fully

• Vent regularly during operations

CAUTION!

If the installation is switched off temporarily, condensate must not be stopped temporarily to remain in

the pipes to avoid freezing and corrosion risk.

For steam, overheated, high temperature coils, to prevent overheating inside the unit, the fan stop must be delayed

by 3 to 5 minutes after the steam valve have been closed.

Electrical heaters

Electric air heaters are provided with automatic and/or manual reset overheat thermostats.

CAUTION!

To prevent over heating inside the unit when the heater is being switched off, the fan maybe switched off

after an over run period of 3 to 5 minutes.

The same shall be done when the unit is installed any other type of high temperature source.

Commissioning procedure