AFDG/AFDU Startup Procedure

AFDG-SVU01L-EN

35

Note:

If the set values do not match, contact the

local Trane Service agency first, or, the

La Crosse Business Unit Technical Service

Department. The correct values are listed

on the unit nameplate shipped with each

unit.

5. In order to view the AFDG/AFDU configurable settings,

go to the Chiller Configuration tab in the Tracer® TU

service tool and select the AFD expanding section.

6. If the drive LLID is not found or if it is necessary to re-

bind the drive LLID, follow the procedure below.

a. The drive’s main DC bus must be charged in order

for the drive LLID to be recognized or bound. Close

the drive disconnect and apply line power to the

drive.

b. With a laptop connected to the chiller and with

Tracer® TU running, enter the binding view menu

of Tracer® TU and locate the “Starter” LLID in the

menu. Select the “Bind” button for the AFD Starter

LLID.

c. The screen “Is the device alone selected?” displays.

In the AFD, wave magnet on the LLID and light the

“service” LED.

d. On the Tracer® TU screen, select the “yes” button

to indicate the LLID has been selected.

e. When properly bound, exit the binding view.

f. Perform any remaining startup items.

7. When ready, start the drive from the Tracer®

AdaptiView™ display.

8. Check the AFDG/AFDU chiller drive response to the

UC800. Initially, the drive will go to 38 hertz and stay

there until the CenTraVac™ chiller vanes open based

on load. The drive will change the speed from there

based on load demand.

9. Document all information on the Startup log.

Drive Settings

Set the values in the order shown in

based on

information obtained from the chiller nameplate.

For additional information, refer to the programming

manual that is shipped with the drive. The programming

manual includes a detailed section that discusses

accessing the parameters in the drive.

This process is summarized briefly below:

1. To access the parameters, press the

Main Menu

key.

2. If required, enter the password (

999

).

3. To select a parameter group, use the up/down arrow

keys to highlight the parameter group, and then press

the

Enter

key to access that group.

4. Use the up/down arrow keys to access the parameter

number, and then press the

OK

key.

5. Use the up/down arrow keys to change the parameter,

and then press the

OK

key to change the setting.

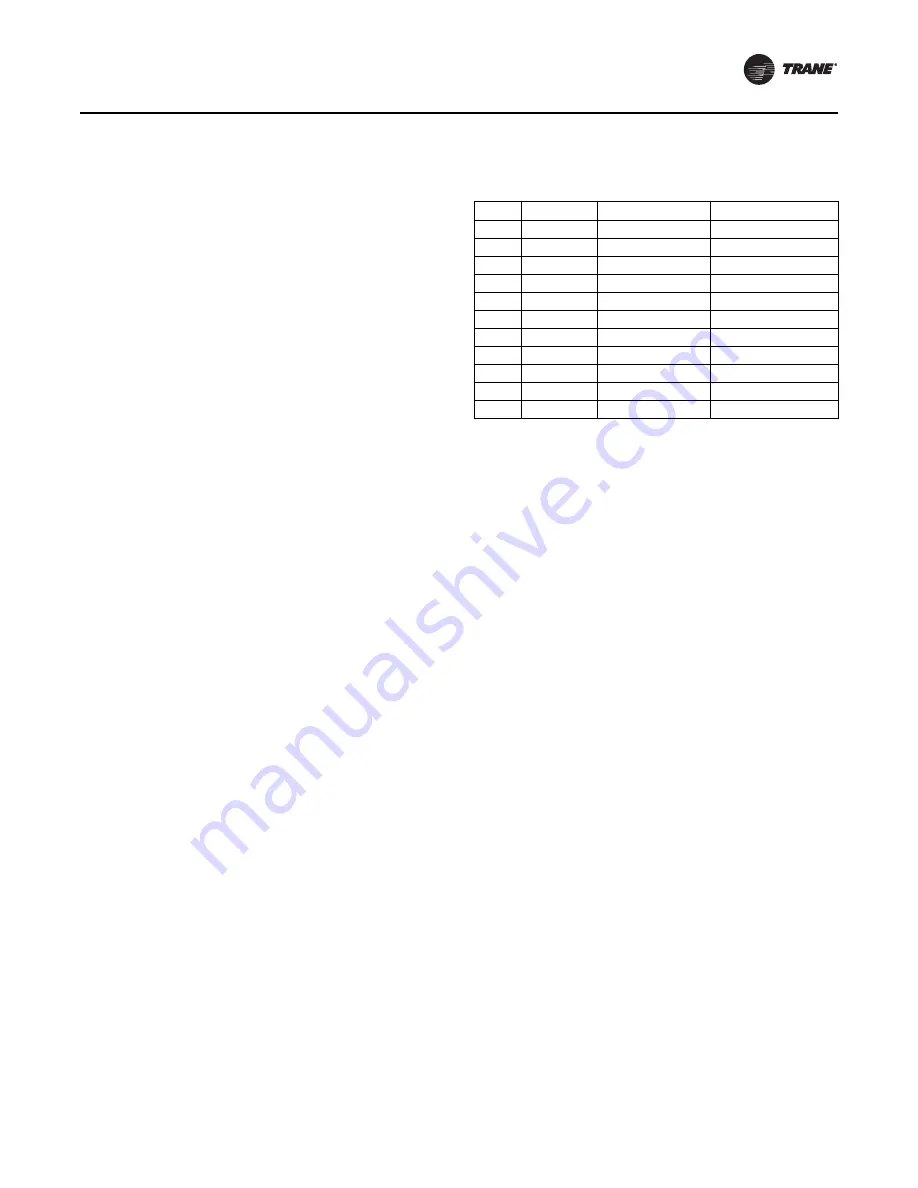

Table 10. Job specific settings

Group Parameter Description

Value

1

20

Motor kW

Set to nameplate CPKW

1

22

Motor voltage

Nameplate voltage

1

24

Motor current

Set to nameplate TVA

1

25

Motor nominal speed Set to nameplate TRPM

1

30

Stator resistance

Set to nameplate SRES

1

35

Main reactance

Set to nameplate MGRE

4

16

Torque limit mode

Set to maximum

4

18

Current limit

Set to maximum

8

(a)

(a) If the customer is connecting to the remote-mounted AFDG with MOD-

BUS®, Group 8 parameters MUST be selected.

01

Control site

1

02

Control word source 0

53

Start select

0

6. If the chiller does not start, re-enter the motor kW,

voltage, and current. The stator resistance and main

reactance values will change based on the motor table

look up that is built into the drive.

If the motor still will

not start,

then perform an AMA (the AMA will

physically measure the stator resistance and main

reactance values, including the connecting cables

between the drive and the motor; the values will then

be set in the drive when the AMA is complete).

To perform an AMA:

a. Change the following parameters:

•

0-40 Hand on key; set to enable.

•

0-41 Off key; set to enable.

•

5-12 Terminal 27 digital input; set to 0, no

function.

b. Go to parameter 1-29 automatic motor adaptation

(AMA) and enter 1 to enable complete AMA.

c. Press the hand key “on” to start the AMA. The

display should now begin to show the steps

completing; there are approximately 16 steps that

need to be completed. If the drive displays an Alarm

53, change the motor voltage value in parameter

1-22 (for example, change from 460 volt to 480 volt

or visa versa) and then try running the AMA again.

d. After the AMA is finished, the display will read

“Press OK to finish AMA.” Press

OK

.

Important:

After the AMA is finished, set parameters

0-40, 0-41, 5-12, and 1-29 back to their

original settings.

7. If the drive is still having difficulty starting the motor, it

may be necessary to perform a reset on the drive; this

procedure will reset the drive parameters back to the

original Danfoss defaults. After this has been

completed, first set the parameters in

and

then set the values in