4

18-GE12D1-8

Installer’s Guide

C. UNIT INSTALLATION

UPFLOW

a.

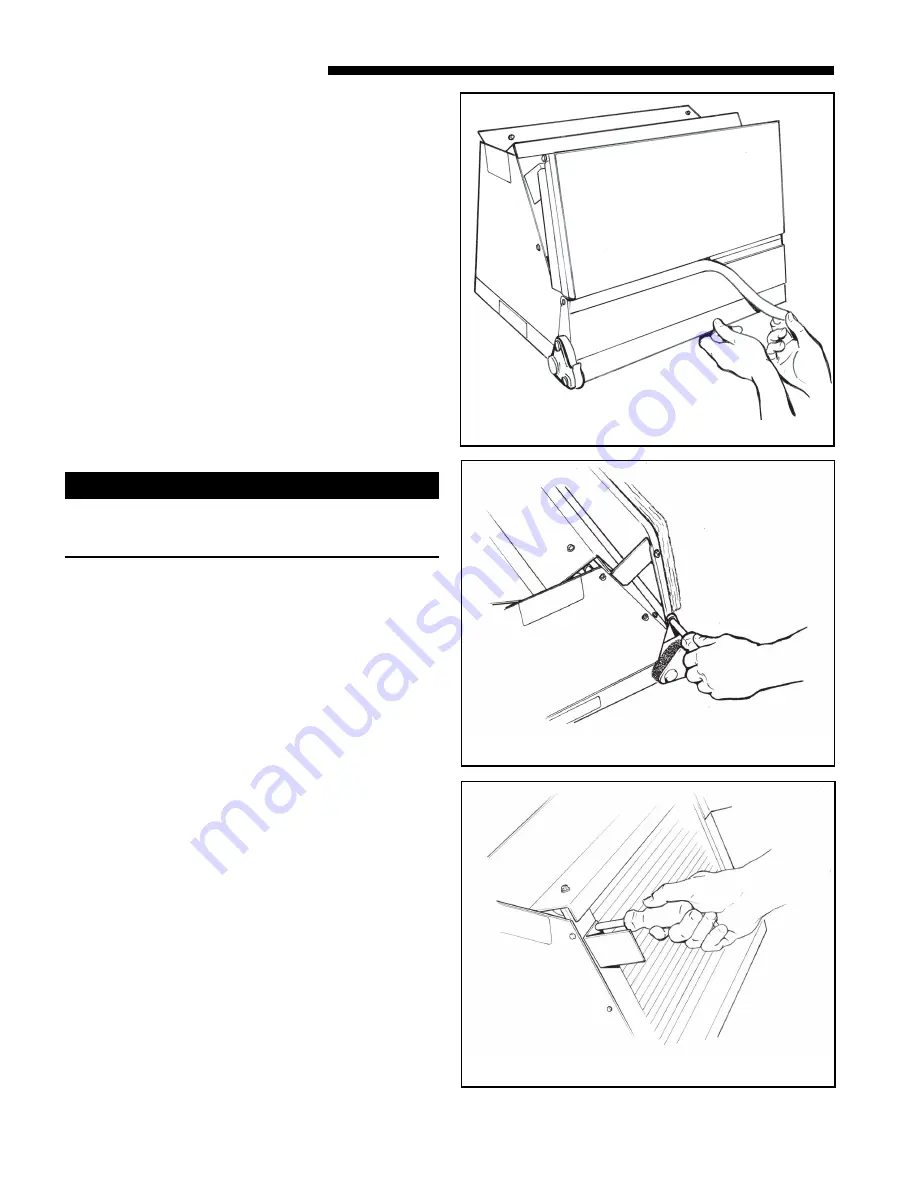

For maximum efficiency

, the horizontal drip

tray should be removed. See Figures 5, 6 and 7.

Tray removal requires that the coil be removed

by sliding the coil out on the coil channel sup-

ports. There is a coil support tab at the top of the

coil connected to the case must be removed first.

Remove 1 inch insulation strip covering the lip of

the drip tray. The tray is detached by removing

the two screws at the drain pan. Remove the two

screws holding the two brackets at the top of the

coil. Remove drip tray by gently breaking the

seal between the drip tray and drain pan.

b. Remove the factory installed baffle assembly

from the apex of the coil by using a 5/16"

nutdriver to remove the screw. Replace this

baffle with the factory supplied narrow coil baffle

using the screws removed previously. See Figure

8. Reinstall coil assembly.

▲

CAUTION

!

When installing the narrow coil baffle, make sure to

align the baffle up with the holes so NOT to puncture

the coil tubing.

c. Position unit on Pedestal or other suitable foun-

dation. If Pedestal is not used, a frame strong

enough to support the total weight must be pro-

vided. Provide a minimum height of 14 inches for

proper unrestricted airflow.

d. If a return air duct is connected to the air han-

dler, it must be the same dimensions as shown in

the outline drawing on page 14.

e. Pedestal and unit should be isolated from the

foundation using a suitable isolating material.

f.

Openings where field wiring enters the

cabinet must be completely sealed.

Location

of power entry is shown on the Outline Drawing.

Use 2.5" clear stickers provided to seal all unused

electrical knockouts. See Figure 13.

g. After ductwork connections are made, seal air-

tight and per Local codes.

DOWNFLOW

a.

For maximum efficiency

, the horizontal drip

tray should be removed. See the Downflow Kit

Installer's Guide 18-GJ23D1-1 for complete in-

structions.

b. If a return duct is connected to the air handler, it

must be the same dimensions as the return

opening shown in the outline drawing on page

15.

Figure 5 Drip Pan Foam Removal

Figure 6 Horitzontal Drip Pan Removal

Figure 7 Drip Pan Bracket Removal