1-4

Engine mechanical (connecting rod and crank shaft)

Structure

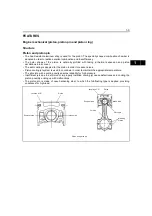

Connecting rod

• The connecting rod is made of forged carbon steel. Its large end is horizontally split, which has

advantages in rigidity. The bush made of lead bronze with the oil groove in the center is pressed in its

small end.

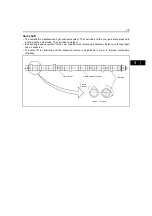

• The connecting rod bolts are tightened by the plastic region tightening method.

• As shown in the illustration, the plastic region tightening method is the way of tightening the bolts in the

plastic region where the change in the axial tension against the extension of the bolt is few. This method

has following characteristics.

Stable axial tension can be obtained: Because fluctuation in the axial tension is small comparing to elastic

region tightening, the axial tension can be stabilized.

High axial tension can be obtained.

There is a limit in reuse: Because plastic elongation is added at every time of it is reused, the frequency of

reuse is limited.

Refer to the J08E engine repair manual ( ) when reusing.

6

Match the bush oil hole with the con rod oil hole

Matching marks

Oil hole

Fitting direction of the bush joint

Connecting rod (Looking at from the front of the engine)