1-5

1

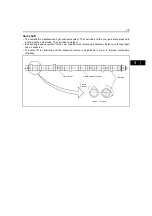

Cam shaft

• The camshaft is manufactured by knockdown system. The cam lobe and the com journal are pressed in

a hollow carbon steel tube. The cam lobe is welded.

• By adopting a special profile for the cam, together with improving inhalation efficiency, quiet operation

can be expected.

• The valve lift is optimized and the intake-air volume is heightened in order to improve combustion

efficiency.

Cam journal

Hollow carbon steel tube

Rotative

direction

Exhaust

Intake

Cam lobe