13

❏

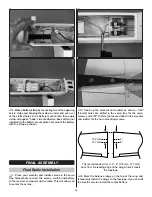

10. Replace the cowl on the fuselage and mount the

spinner with a propeller. Insert 3/32" [2.5mm] balsa shims

between the cowl and the spinner and tightly tape the cowl

to the spinner making sure they are aligned.

❏

11. Mark two cowl screw holes on both sides of the cowl

1" [25mm] ahead of the lines you marked earlier.

❏

12. Drill 3/32" [2.4mm] holes at the marks through the

cowl and into the fuselage.

❏

13. Enlarge the holes

in the cowl only

with a 1/8" [3.2mm]

drill. Wipe away all the ink lines with a small paper towel

square dampened with denatured alcohol and mount the

cowl with four M3 x 10 screws.

❏

14. Now that the cowl is mounted you can see where

more trimming may be required for a perfect fit around the

engine, carburetor, etc. Mark the cowl where additional

trimming is required. Also cut holes for the muffler screws

and attach the muffler (cutting the cowl where necessary

to accommodate these parts).

❏

15. Remove the cowl and trim as necessary. Finally, install

the needle valve, then mount the cowl. The needle valve is

close enough to the cowl that you can press on the cowl

over it to make a dimple indicating where to begin cutting

for the needle valve, or you can mark the inside of the cowl

with a pencil.

❏

16. Trim the cowl as necessary to allow access to the

needle valve. Also cut holes in the cowl for the fueling line

from the fuel tank, for the pressure line from the muffler and

for the muffler screws.

❏

17. Once all the holes are cut in the cowl, smooth the

rough-cut edges and remove any loose fibers with 320-grit,

then 400-grit sandpaper.