Schematic Diagrams

10-2

Toshiba

For schematic Diagram

- Resistors are in ohms, 1/8W unless otherwise noted.

Note

Special note :

Most semiconductor devices are electrostatically sensitive and therefore require the special handling techniques described under the

“electrostatically sensitive (ES) devices” section of this service manual.

Note :

Do not use the part number shown on this drawing for ordering. The correct part number is shown in the parts list (may be slightly different

or amended since this drawing was prepared).

Important safety notices :

Components identified with the mark have the special characteristics for safety. When replacing any of these components.

Use only the same type.

◆

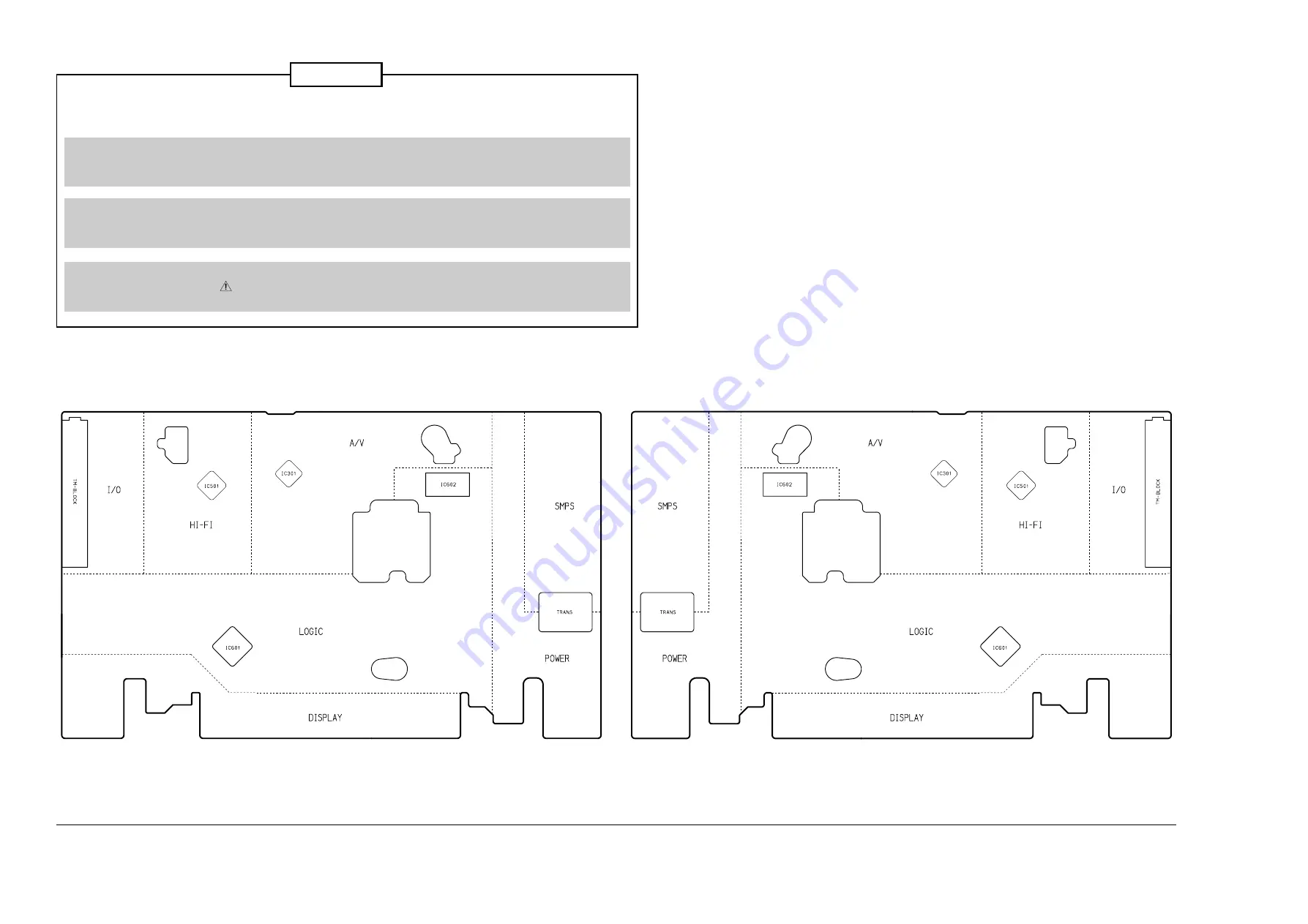

Block Identification of Main PCB

Component Side

Conductor Side

Summary of Contents for W-412

Page 16: ...Reference Information 2 12 Toshiba 2 2 1 IC301 LA71200M 2 2 IC Blocks ...

Page 17: ...Reference Information Toshiba 2 13 2 2 2 IC601 MN101D02D ...

Page 47: ...Exploded View 6 2 Toshiba 6 1 Packing Assembly Y101 A702 A701 Y102 UT01 A702 ...

Page 58: ...Toshiba 8 1 8 Block Diagram HI FI MODEL ONLY ...

Page 59: ...Toshiba 9 1 9 PCB Diagram 9 2 9 1 Main ...

Page 60: ...PCB Diagram 9 2 Toshiba 9 1 Main ...

Page 61: ...PCB Diagram Toshiba 9 3 ...

Page 64: ...Schematic Diagrams Toshiba 10 3 10 1 S M P S Power ...

Page 65: ...Schematic Diagrams 10 4 Toshiba 10 2 Logic ...

Page 66: ...Schematic Diagrams Toshiba 10 5 10 3 A V ...

Page 67: ...Schematic Diagrams 10 6 Toshiba 10 4 TM Block Input Ouput ...

Page 68: ...Schematic Diagrams Toshiba 10 7 10 5 Display ...