– 20 –

• Do not use in bathrooms or food preparation areas etc.

If you use the unit at the place of much soot and high humidity, the filter or the Heat Exchanger gets clogged

and disables you to use it.

• Use the Heat Exchange Ventilators in the ambient temperature of 40°C or less.

Never install the unit at the place where the flame likely reaches directly the unit. If you use it at the atmosphere of

more than 40°C for hours, it is likely to cause deterioration or deformation or damage of the resin part.

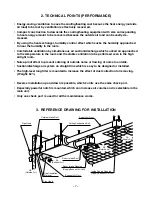

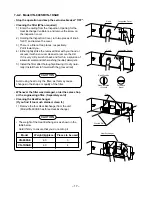

• Be careful of dewing and frosting.

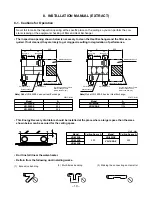

As shown in the figure to the right, suppose a high temp. absorbing air condi-

tion A and a low temp absorbing air condition B are plotted on the air line

figure, then a high temp air A is heat-exchanged by the unit and goes out of

the saturation curve as shown by Point C. In this case, the unit will be dewed

or frosted. To avoid this, you are required to heat a low temp air B up to B' so

as to get C' below the saturation curve, before using the unit.

8-2. Local Procurements

• Switches are to be locally procured.

We recommend that you use a switch having more than 3mm distance to break contact and more than 15A

rated current.

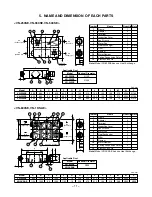

8-3. Reference Sketch

A

B

C

C'

B'

Dry-bulb temperature (˚C)

Saturation

curve

Absolute humidity (kg/kg

’)

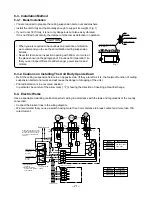

Pipe Hood

Outside Intake Duct

Supply Air Duct

Ceiling Suspension Bolt

Room Intake Duct

Room Intake Opening

(Supply/Exhaust Air Grill)

Heat Insulation

Material

Exhaust Air Duct

Inside Supply Opening

(Supply/Exhaust Air Grill)

Pipe Hood

OA

(Outside Air)

RA

(Outside Air)

SA

(Supply Air)

EA

(Exhaust Air)

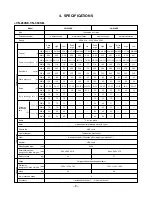

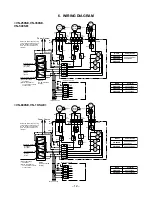

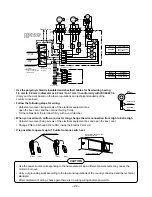

Use conditions

Outdoor air conditions : Temperature range –10°C~40°C, relative humidity 85% or less

Indoor air conditions

: Temperature range –10°C~40°C, relative humidity 85% or less

Installation requirements: Same as the indoor air conditions

• Indoor air here means air in air-conditioned living rooms. Its use in refrigerators or other places where

temperature can fluctuate greatly is prohibited even if a temperature range is acceptable.

Example: Indoor air conditions

During cooling period : Temperature 27°C, relative humidity 50%

During heating period : Temperature 20°C, relative humidity 40%

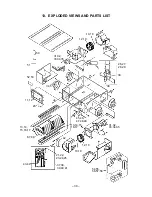

Summary of Contents for VN-1KSAE

Page 32: ......