11

12

■

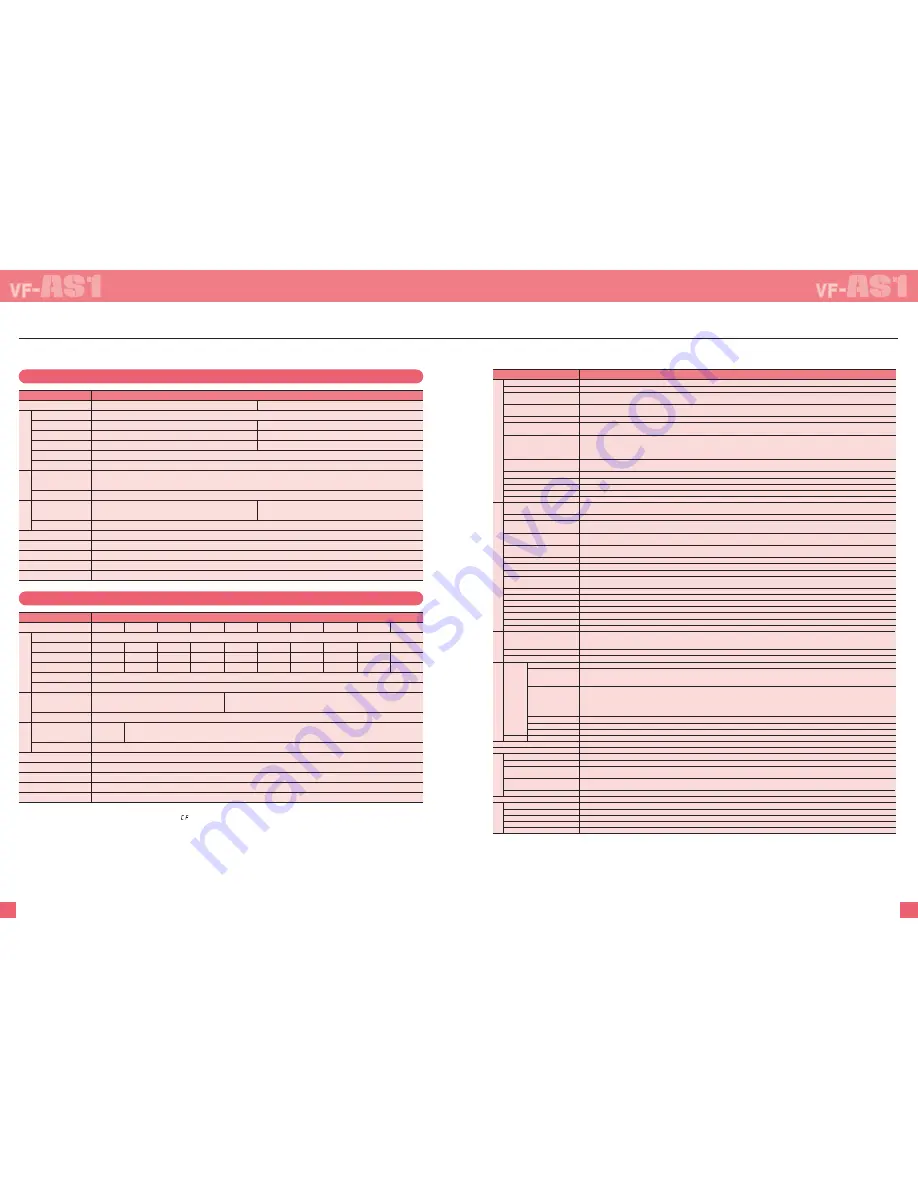

Standard specifications (200 V class -55 to 75 kW, 400 V class -90 to 500 kW model)

■

Common Specifications

200 V class

400 V class

Note 1) Capacity is calculated at 220V for the 200V models and at 440V for the 400V models.

Note 2) Indicates the value when the PWM carrier frequency (parameter ) is 2.5 kHz or less.

When low noise (PWM carrier frequency 8 kHz) is required at 18.5 kW or more, use an inverter of capacity one rank higher than the motor capacity.

Note 3)

±

10% when the inverter is used continuously (load of 100%)

Note 4) Inverters, 18.5kW or greater, do not have wiring port covers. They have large openings, but there is no space to bend the external cables inside the unit. If they are fitted

external to the cabinet, please use an optional wiring port cover.

Note 5) For 200V-55kW, 400V-90kW or larger model, be sure to install DC reactor.

However, this is unnecessary for DC input specifications.

Note 6) Three-phase 380~480V-50/60Hz for 4900PC

Note 7) Complies with the European EMC Directive

IEC/EN61800-3, 2nd environment, category C3

Item

Specification

Applicable Motor (kW)

Type

Form

Output Capacity (kVA)

Note 1)

Output Current (A)

Note 2)

Output Voltage

Overload Current Rating

Dynamic

Braking Circuit

Dynamic Breaking Resistor

Voltage/frequency

Allowable Fluctuation

Protective method

Cooling method

Color

Built-in Filter

DC Reactor

VFAS1–

3-phase, 200 to 240 V (The maximum output voltage is the same as the input voltage.)

150%–1 minute, 165%–2 seconds

Built-in

Compatible with external options

V10% – 15%

Note 3)

Frequency

±

5%

IP20 enclosed type (JEM1030)

Note 4)

Forced air cooling

RAL7016

External filter (optional)

Attached DC reactor

Note 5)

55

2550P

84

221

75

2750P

109

285

3-phase, 200 to 240 V – 50/60 Hz

3-phase, 200 to 220 V – 50 Hz

3-phase, 200 to 240 V – 60 Hz

Item

Specification

Applicable Motor (kW)

Type

Form

Output Capacity (kVA)

Note 1)

Output Current (A)

Note 2)

Output Voltage

Overload Current Rating

Dynamic

Braking Circuit

Dynamic Breaking Resistor

Voltage/frequency

Allowable Fluctuation

Protective method

Cooling method

Color

Built-in Filter

DC Reactor

90

4900PC

136

179

110

4110KPC

164

215

132

4132KPC

197

259

160

4160KPC

239

314

200

4200KPC

295

387

220

4220KPC

325

427

280

4280KPC

419

550

355

4355KPC

511

671

400

4400KPC

578

759

500

4500KPC

717

941

VFAS1–

3-phase, 380 to 480 V (The maximum output voltage is the same as the input voltage.)

150%–1 minute, 165%–2 seconds

Compatible with external options

3-phase, 380 to 440 V – 50 Hz

3-phase, 380 to 480 V – 60 Hz

V10% – 15%

Note 3)

Frequency

±

5%

IP20 enclosed type (JEM1030)

Note 4)

Forced air cooling

RAL7016

EMI noise filter

Note 7)

Attached DC reactor

Note 5)

Built-in

Compatible with external options

Note 6)

Standard specifications

Rating

Po

w

e

r

Supply

Electr

ic

Br

aking

Rating

Po

w

e

r

Supply

Electr

ic

Br

aking

Item

Specification

Control specifications

Oper

ation specifications

Protectiv

e

function

Displa

y

functions

Output signal

En

vironments

Note 1: 16 contact input terminals (of which 8 are options) are programmable contact input terminals, and they make it possible to arbitrarily select from 136 types of signals.

Note 2: Programmable ON/OFF output terminals make it possible to arbitrarily select from 150 types of signals.

Note 3: Programmable analog output terminals make it possible to arbitrarily select from 55 types of signals.

Note 4: When using inverters where the ambient temperature will rise above 50

°

C, remove the upper cover and operate each inverter at a current lower than the rated one.

Note 5: This function protects inverters from overcurrent due to output circuit ground fault.

4-digit and

7-segment

LED

Sinusoidal PWM control

LED

Main circuit voltage feedback control. (Switchable between automatic adjustment/fix/control off)

Setting between 0.01 to 500Hz. Default max. frequency is set to 0.01 to 60Hz.

Maximum frequency adjustment (30 to 500Hz)

0.01Hz: operation panel input (60Hz base),

0.02Hz: analog input (60Hz base, 11 bit/0 to 10Vdc)

Within

±

0.2% (25

°

C

±

10

°

C): analog input

±

0.01% (25

°

C

±

10

°

C): digital input

V/f constant, square reduction torque control, automatic torque boost, vector calculation control, base frequency adjustment 1, 2, 3, and 4 (25 to 500Hz), V/F 5-point arbitrary setting,

torque boost adjustment (0 to 30%), start frequency adjustment (0 to 10Hz), stop frequency adjustment (0 to 30Hz)

3k

Ω

potentiometer (possible to connect to 1 to 10k

Ω

-rated potentiometer)

0 to 10Vdc (input impedance Zin: 30k

Ω

)

0 to

±

10Vdc (Zin: 22k

Ω

)

4 to 20mAdc (Zin:242

Ω

)

The characteristic can be set arbitrarily by two-point setting. Compliant with 6 types of input; analog input (RR, VI/II, RX, RX2), pulse input and binary/BCD input (*RX2, binary/BCD

input: optional)

3 places. Setting of jump frequency and width.

Upper limit frequency: 0 to max. frequency, lower limit frequency: 0 to upper limit frequency

Adjustment of proportional gain, integral time, differential time and delay filter

200V-45kW or less, adjustable between 1.0 to 16kHz for 400V-75kW or less200V-55kW or less, adjustable between 1.0 to 8kHz for 400V-90kW or more

Voltage command input specification: DC 0 to

±

10V

0.01 to 6000 sec. Selectable from among acceleration/deceleration. times 1, 2, 3 and 4. Automatic acceleration/deceleration function. S-pattern acceleration/deceleration 1 and 2

pattern adjustable.

Adjustment of braking start frequency (0 to 120Hz), braking (0 to 100%) and braking time (0 to 10 sec.). With emergency stop braking function and motor shaft fix control function.

With F-CC closed to forward run, with R-CC closed to reverse run, with both closed to reverse run. With ST-CC opened to coast stop. Emergency stop by panel operation or terminal

board.

Jog mode, if selected, allows jog operation from the operation panel

Jog run operation by terminal board is possible by setting the parameters.

By changing the combination of open/close between S1, S2, S3, RR/S4-CC, set fre 15-speed operation.

Selectable between acceleration/deceleration time, torque limit and V/f by set frequency.

Capable of restarting after a check of the main circuit elements in case the protective function is activated. Max. 10 times selectable arbitrarily. Waiting time adjustment (0 to 10 sec.)

The cooling fan will be stopped automatically to assure long life when unnecessary.

Possible to keep the motor running using its regenerative energy in case of a momentary power failure. (Default: OFF)

Possible to select each 8 patterns in 2 groups from 15-speed operation frequency. Max. 16 types of operation possible. Terminal board operation/repeat operation possible.

Possible to switch operation by commercial power source or inverter

Increases the operating efficiency of the machine by increasing the rotational speed of the motor when it is operated under light load.

When two or more inverters are used to operate a single load, this function prevents load from concentrating on one inverter due to unbalance.

External input signal adjustment is possible to the operation frequency command value.

Switchable between standard motor/constant torque VF motor, adjustment of overload protection and stall prevention level.

Reset by 1a contact closed (or 1b contact opened), or by operation panel. Or power source OFF/ON. This function is also used to save and clear trip records.

Stall prevention, current limit, overcurrent, overvoltage, short circuit on the load side, ground fault on the load side (Note 5), undervoltage, momentary power failure (15ms or more),

non-stop control at momentary power failure, overload protection, arm overload at starting, overcurrent on the load side at starting, overcurrent and overload at dynamic braking

resistance, fin overheat, emergency stop

Key prohibition selectable between Stop key only, Mode key only, etc. All key operations can be prohibited.

Automatic load reduction control at overloading. (Default: OFF)

Possible to restart the motor in coasting in accordance with its speed and direction. (Default: OFF)

Control system

Output voltage adjustment

Output frequency range

Minimum setting steps of frequency

Frequency accuracy

Voltage/frequency characteristics

Frequency setting signal

Terminal board base frequency

Frequency jump

Upper and lower limit frequencies

PWM carrier frequency

Torque control

DC braking

Forward run/reverse run Note 1)

Jog run Note 1)

Preset speed operation Note 1)

Retry

Soft stall

Cooling fan ON/OFF

Operation panel key operation ON/OFF

control

Regenerative power ride-through control

Auto-restart operation

Simplified pattern operation

Commercial inverter switching

Light-load high-speed operation

Drooping function

Override function

Protective function

Electronic thermal characteristic

Reset

Acceleration/deceleration time

PID control

Input/output terminal input function

Sink/source switching

Failure detection signal

Low speed/speed reach signal output Note 2)

Upper/lower limit frequency signal output

Note 2)

Output for frequency meter/output for ammeter

Note 3)

Pulse train frequency output

Communication function

Operating environments

Ambient temperature

Vibration

Storage temperature

Relative humidity

Stall prevention during operation, overload limit, overload, undervoltage on power source side, DC circuit undervoltage, setting error, in retry, upper limit, lower limit.

Overcurrent, overvoltage, fin overheat, short circuit on the load side, ground fault on the load side, inverter overload, arm overcurrent at starting, overcurrent on the load side at starting,

EEPROM error, RAM error, ROM error, transmission error, (dynamic braking resistor overcurrent/overload), (emergency stop), (undervoltage), (low current), (overtorque), (motor

overload), (output phase failure) The items in the parentheses are selectable.

Operation frequency, operation frequency command, forward run/reverse run, output current, DC voltage, output voltage, compensated frequency, terminal board input/output

information, CPU version, control EEPROM version, past trip history, cumulative operation time, speed feedback, torque, torque command, torque current, exiting current,

PID feedback value, motor overload factor, inverter overload factor, PBR overload factor, PVBR load factor, input power, output power, peak output current, peak DC voltage,

Motor counter pseudo PG, position pulse, RR input, VI/II input, RX input, RX2 input, FM output, AM output, meter adjustment fix output, flash memory version, main circuit

EEPROM version, types of connection option, previous default setting, previous automatic control (AU2)

Display of optional units other than output frequency (motor speed, line speed, etc), current ampere/% switch, voltage volt/% switch

Searches automatically parameters that are different from the standard default setting parameters. Easy to find changed parameters.

User parameter settings can be saved as default settings. Allows to reset the parameters to the user-defined parameter settings.

Displays main circuit capacitor charging.

Possible to select positive logic or negative logic with programmable input/output terminal function menu. Note 1: Note 2: (Default setting: positive logic)

Possible to switch between minus common (CC) and plus common (P24) for control terminal. (Default setting: minus common (CC))

1c contact output (250Vac-2A-cosØ=1, 250Vac-1A-cosØ=0.4, 30Vdc-1A)

Open collector output (24Vdc, max. 50mA, output impedance: 33

Ω

)

Open collector output (24Vdc, max. 50mA, output impedance: 33

Ω

)

Analog output. 1mAdc full-scale DC ammeter or 7.7Vdc-1mA voltmeter

Open collector output (24Vdc, max. 50mA)

RS-485 standard 2-channel equipped (connector: modular 8P)CC-Link, DeviceNet and PROFIBUS-DP are optional.

Indoor use. Altitude: 3000m or less (current reduction necessary if 1000m or more.) Place not exposed to direct sunlight and free of corrosive and explosive gases.

-10 to +60

°

C (Remove the upper cover if 40

°

C or more, max. 60

°

C) Note 4:

-25 to +65

°

C

20 to 93% (free from condensation)

5.9m/s

2

{0.6G} or less (10 to 55Hz) (Compliant with JIS C0040)

Causes of failures

Free unit display

Alarms

Charge display

User default setting

Automatic edit function

Monitoring function