3. REPLACEMENT OF MECHANICAL PARTS

3-1. Lamp Assembly

1-2

CAUTIONS BEFORE SERVICING

Electronic parts are susceptible to static electricity and may easily be damaged, so do not forget to take

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screwdriver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to

secure metal parts. If they are used improperly, the screw holes will be easily damaged and the parts can

not be fixed.

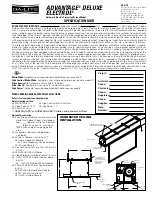

Step

Figure

Explanation

1

2

3

4

Loosen 2 screws (M3 x 8).

These screws are retained with split washers.

Remove the lamp cover.

Loosen 2 screws that secure the lamp module (M3 x 8).

These screws are retained with split washers.

Lift the lamp module and slide out from the projector.