–

56

–

1

0

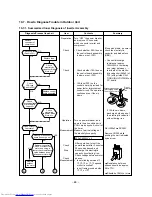

-5. Judgement of Trouble by Every Symptom

1

0

-5-1. Indoor unit (Including remote controller)

Turn off power

supply once, and 5

second later, turn it

on again.

Is OPERATION

lamp blinking?

NO

YES

NO

NO

YES

YES

Is it possible to

turn on power

supply by

pressing

[START/STOP]

button on

remote control?

Does

transmission

mark on

remote control

flash normally,

and is its signal

transmitted

properly?

Remote control is

defective.

Refer to (5)

“Troubleshooting for

Remote Control.”

Is fuse (F01)

of indoor control

board blown?

Is voltage

(DC 12V or 5V)

indicated on

rear of indoor

control board

normal?

Microcomputer

is defective.

Replace main

P.C. board.

Refer to

<Primary check>

or this problem

is one step short

of power P.C.

board block.

Is DC

310 – 340V

suppalied to

primary side of

transfer switch?

Are DC 15V,

DC 12V and

DC 7V

supplied to

secondary

side of

transfer

switch?

Turn off breaker

once and turn it

on again after

removing motor.

Transfer switch,

IC (IC01) for

power supply or

fan motor is

defective.

Replace motor.

YES

YES

NO

NO

NO

NO

YES

YES

YES

NO

NO

YES

Does

fan motor

connector

between

1

and

2

short-circuit?

Unit operates

normally.

Are DC 15V,

DC 12V or

DC 7V

supplied to

secondary

side of

transfer

switch?

Operation

Measure

Item by symptoms

Check item

Conceivable principle

cause

Parts

(R04, C01,

DB01, C03, R01

IC01 and T01)

are defective.

•

Be sure to disconnect the motor connector CN10 after shut off the power supply, or it will be a cause of

damage of the motor.

(1) Power is not turned on (Does not operate entirely)

Summary of Contents for RAS-3M23YACV-E

Page 66: ... 66 10 8 2 P C Board Layout Top View Bottom View ...

Page 80: ... 80 CN600 MCC 758 ...

Page 81: ... 81 MCC 775 ...