2. PRINTER SETUP

ENGLISH VERSION

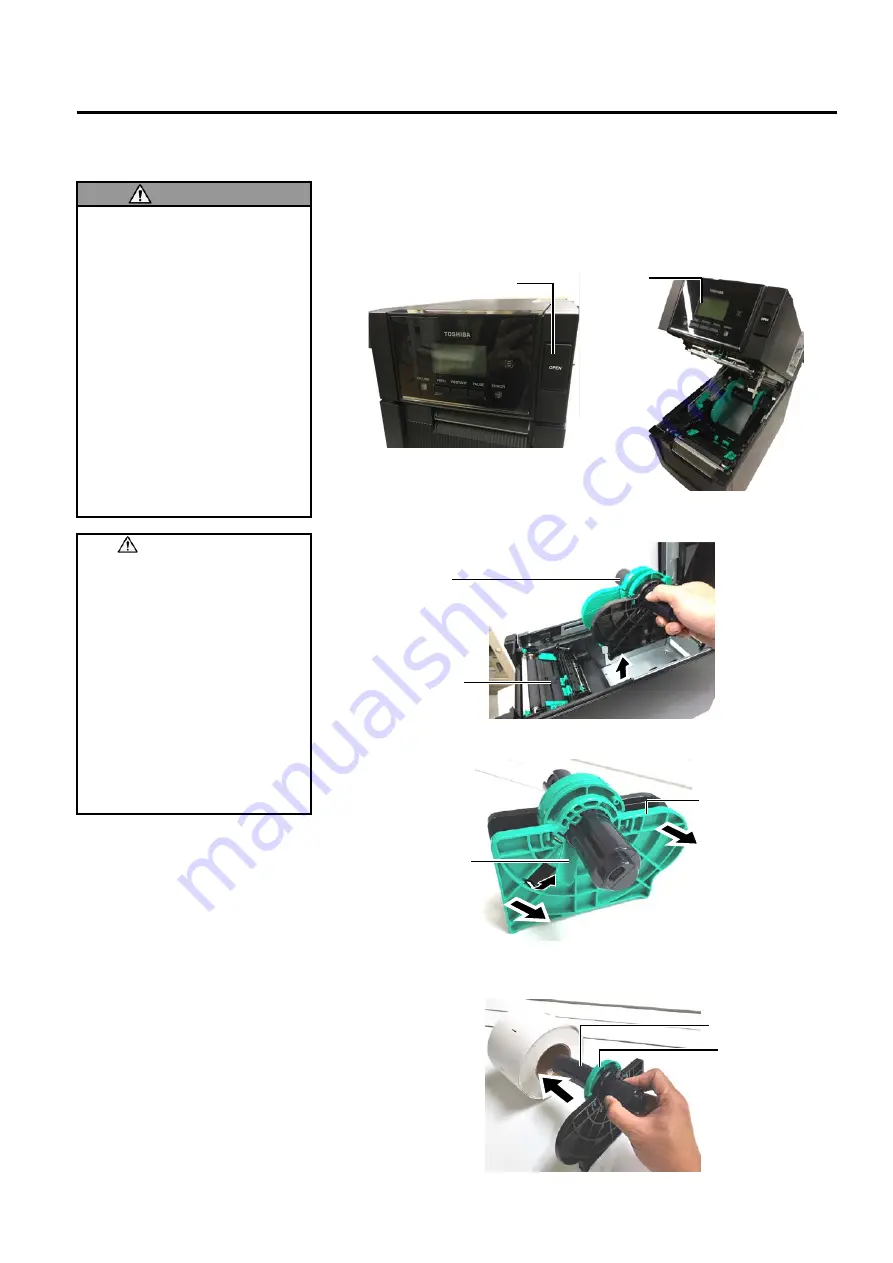

2.3 Loading the Media

E2-

3

2.3 Loading the Media

The following procedure shows the steps to properly load the media into

the printer so that it feeds straight and true through the printer.

Use the same procedure when replacing the media, also.

The printer prints both labels and tags.

1.

Press

the Top Cover Release Button and

gently

open the Top Cover to

its fully open position supporting it with your hand.

2.

Take out the Media Holder Ass’y from the printer.

3.

Raise the Release Lever and remove the Media Holder (Left).

4.

Insert the Media Shaft into the core of a media roll.

1. Do not touch any moving

parts. To reduce the risk of

fingers, jewellery, clothing,

etc., being drawn into the

moving parts, be sure to

load the media once the

printer has stopped moving

completely.

2. The Print Head becomes

hot immediately after

printing. Allow it to cool

before loading the media.

3. To avoid injury, be careful

not to trap your fingers

while opening or closing the

cover.

WARNING!

CAUTION!

1. Make sure that the Upper

Sensor Ass’y is closed

when taking out the Media

Holder Ass’y. If the Upper

Sensor Ass’y is opened, it

may be damaged.

2. Be careful not to touch the

Print Head Element when

opening the Top Cover.

Failure to do this may cause

missing dots by static

electricity or other print

quality problems.

Media Holder (Left)

Release Lever

Media Holder

Ass’y

Top Cover

Upper Sensor Ass’y

Media Shaft

Spacer

Top Cover Release Button