2. MAJOR UNIT REPLACEMENT

EO18-33032

(Revision Date: Jul., 2019)

2.12 Replacing the Wifi Module

2-36

6) When the setting is completed, click

[Set Parameter]

to transfer the data to the printer.

Point

:

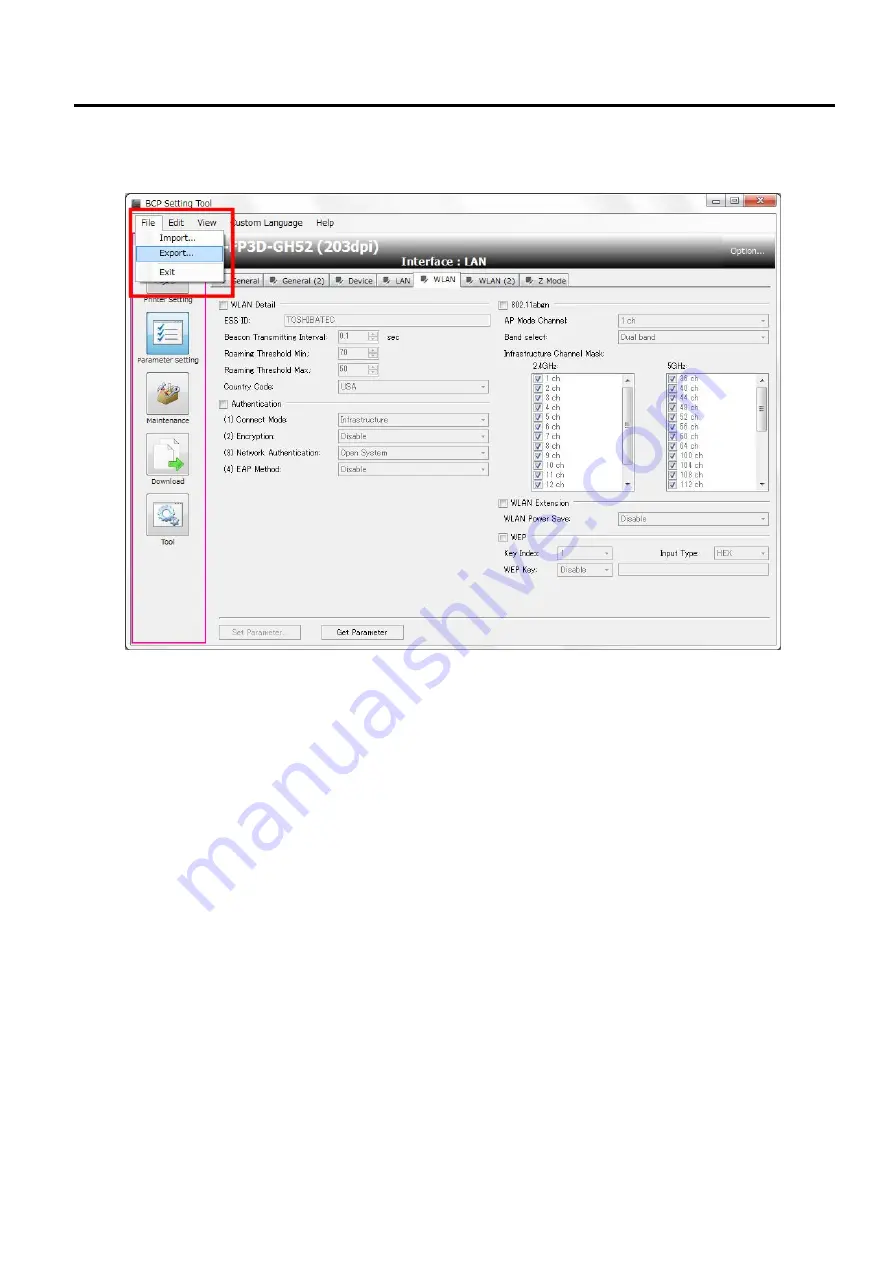

Printer setting record information can be output/saved as “Setting Information Files (*.Xml)”.

This information can be input/reused at next printer parameter setting change.