55

4300 Series Installation and Operation Manual

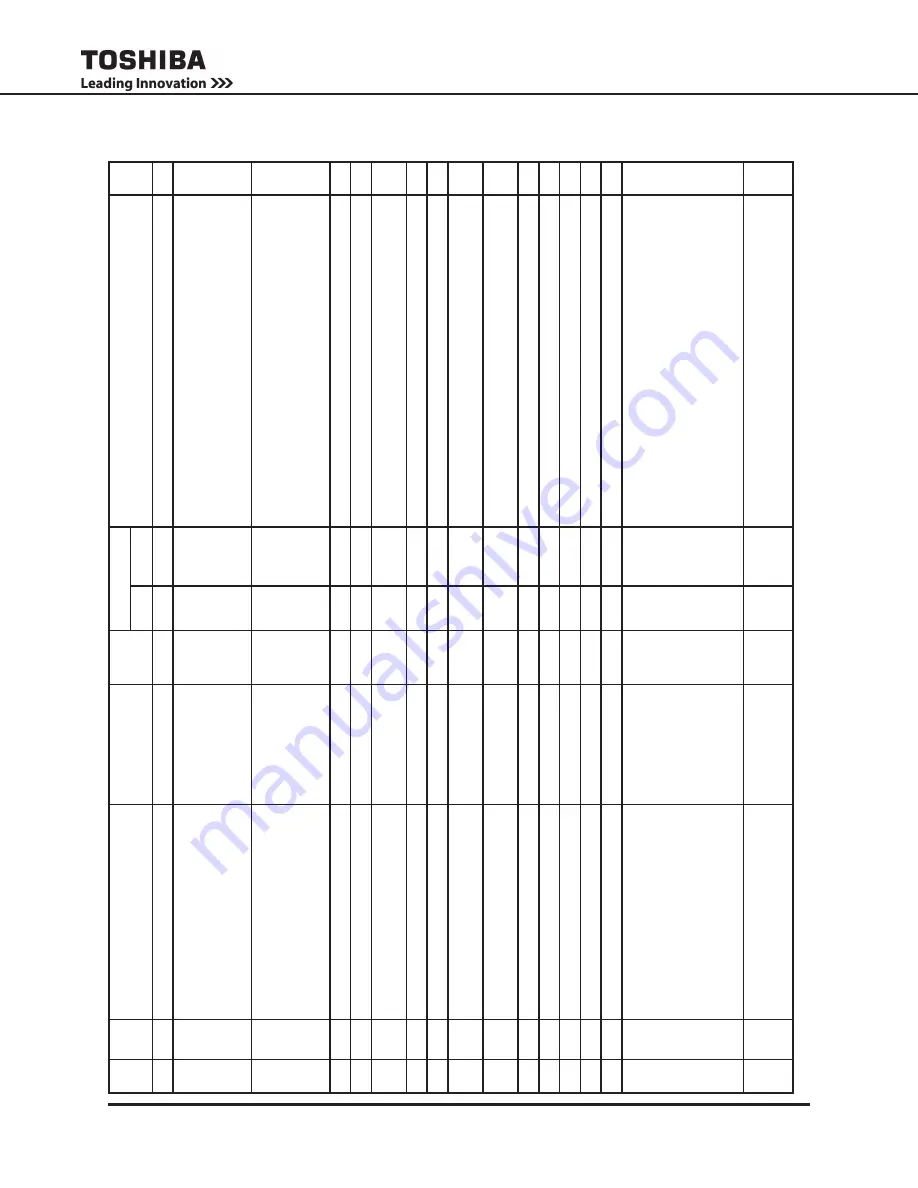

Blk

Item

Long Description

Short Descrip

-

tion

(Inside

UPS)

Units

Permissions

Remark

RE III

User

Admin

6

13

UPS Status(Comm)

UPS Status(Comm)

R

R

þ

6

25

Service Port Baud Rate

Srv Port Baud

R

R

“0 - 9600

1 - 19200

2 - 38400

3 - 57600

4 - 1

15200”

þ

6

27

RMTI3 Port Baud Rate

RMTI3 Port Baud

R

R

“0 - 9600

1 - 19200

2 - 38400

3 - 57600

4 - 1

15200”

þ

6

31

Change Secu. Lvl

Change Secu. Lvl

R/W

R/W

þ

6

32

Manage Admin

PW

Manage Admin

PW

-

R/W

þ

6

33

Reset Admin

PW

Reset Admin

PW

R/W

R/W

“0 - Nothing

1 - Reset”

ý

6

39

Enable Remote Eye to Control UPS

En REye UPS Ctl

-

R/W

ý

6

41

Inverter Start

Inverter Start

R

R/W

þ

6

42

Remote Switch

Remote Bypass Switch

-

R/W

þ

6

67

Auto T

ransfer

AutoXfer

R

R/W

“255 or 1 - Enable

0 - Disabled”

þ

7

01

System

Operation T

ime

System

Op T

ime

Sec

R

R

þ

7

02

Inverter

Op T

ime

Inverter

Op T

ime

Sec

R

R

þ

7

23

Total Backups

Total Backups

R

R

þ

7

25

Total Faults

Total Faults

R

R

þ

7

27

Total Operations

Total Operations

R

R

þ

8

01

Display Firmware V

ersion

DFW V

er

R

R

“UXXYFVMMRRR

T -

Toshba UPS

XX - 2

Alpha Numeric UPS Product Line (43 - 4300)

Y - uC Projects (M - Main, S - Sub, D - Display)

FV - Firmware V

ersion

MM - Major version

RRR - Minor version

Note: Only display can write. Others, read only

.”

þ

8

02

Display Firmware Built Date

DFW BDate

R

R

“Mmm

DD, YYYY

(Ex. Jan 04, 2006

Automatically read by compiler)

Note: Only display can write. Others, read only

.”

þ