This machine produces sound levels in excess

of 85 dBA at the operators ear and can cause

hearing loss through extended periods of

exposure.

Wear hearing protection when operating this

machine.

The use of protective equipment for eyes, ears, feet and

head is recommended.

G000504

1

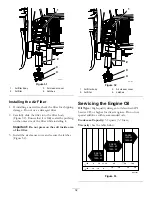

Figure 9

1.

Warning— wear hearing protection

Operating the Parking Brake

Always set the parking brake when you stop the

machine or leave it unattended.

Setting the Parking Brake

1. Move the motion control levers (Figure 15) out to

the neutral lock position.

2. Pull up and back on the parking brake lever to set

the parking brake (Figure 10). The parking brake

lever should stay firmly in the engaged position.

Parking brake may not hold machine parked

on a slope and could cause personal injury or

property damage.

Do not park on slopes unless wheels are

chocked or blocked

Releasing the Parking Brake

Push forward and down on the parking brake lever

to release the parking brake (Figure 10). The parking

brake is disengaged and the lever will rest against the

brake stop.

G000964

1

2

3

Figure 10

1.

Parking brake-ON

3.

Brake Stop

2.

Parking brake-OFF

Starting and Stopping the

Engine

Starting the Engine in Normal Weather

1. Raise the ROPS up and lock into place, sit on the

seat and fasten the seat belt.

2. Move the motion controls to the neutral locked

position.

3. Set the parking brake; refer to Setting the Parking

Brake.

4. Move the PTO (power take off) switch to the off

position (Figure 11).

5. Move the throttle lever to the middle position

(Figure 13).

6. Turn the ignition key clockwise to the run position

(Figure 12).

7. Push the glow plug switch for 10 seconds. The light

will turn on.

8. Release the switch after 10 seconds. The light will

turn off.

18