Drive System

Maintenance

Checking the Tire Pressure

Check the pressure at the valve stem after every

50 operating hours or monthly, whichever occurs

first (Figure 41).

Maintain the air pressure in the rear tires at 13 psi

(90 kPa). Uneven tire pressure can cause uneven

cut. Check the tires when they are cold to get the

most accurate pressure reading.

Note:

The front tires are semi-pneumatic tires

and do not require air pressure maintenance.

Figure 41

Adjusting the Caster Pivot

Bearing

Check after every 500 operating hours or at

storage, which ever comes first.

1. Disengage the PTO, move the motion control

levers to the neutral locked position and set

the parking brake.

2. Stop the engine, remove the key, and wait for

all moving parts to stop before leaving the

operating position.

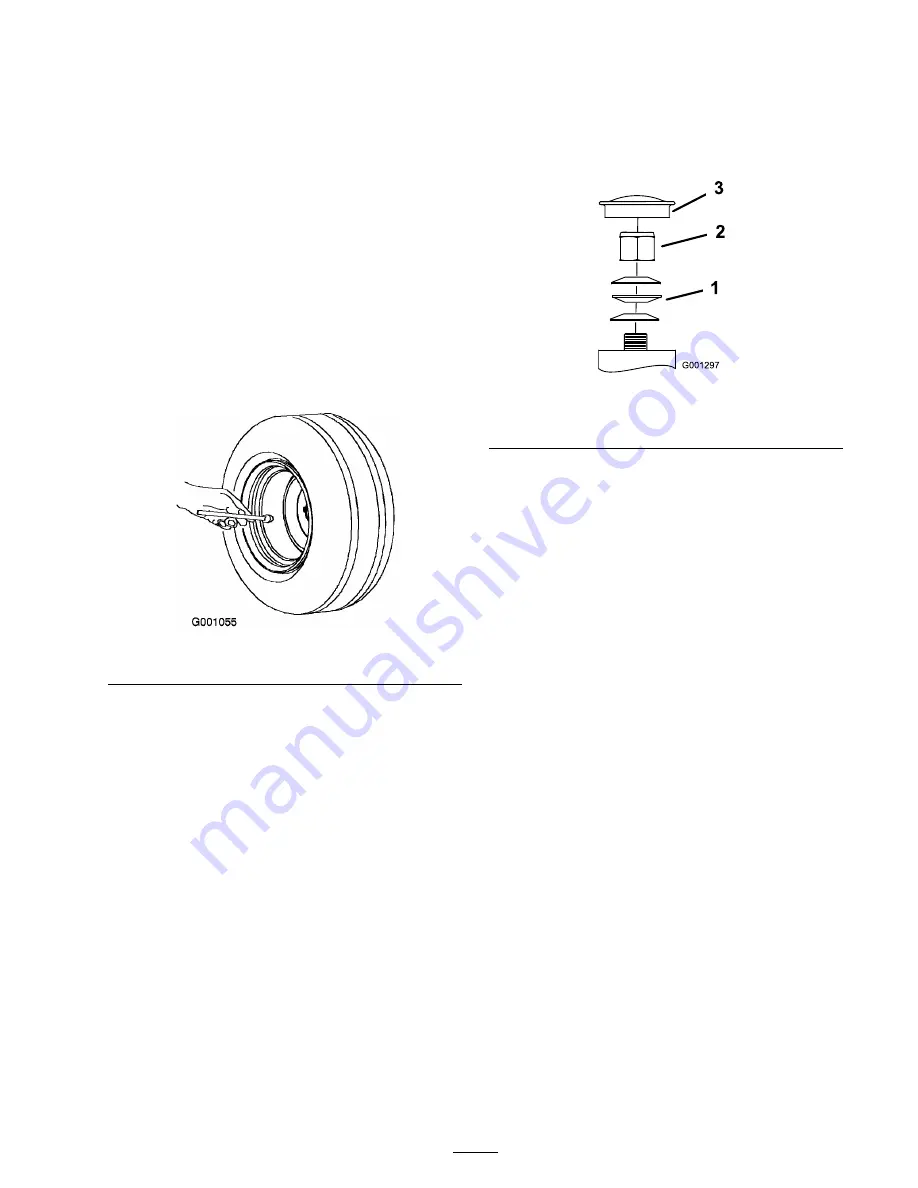

3. Remove the dust cap from caster and tighten

lock nut (Figure 42).

4. Tighten the locknut until the spring washers

are flat and then back off a 1/4 turn to properly

set the pre-load on the bearings (Figure 42).

Important:

Make sure spring washers

are installed correctly as shown in

Figure 42.

5. Install the dust cap (Figure 42).

Figure 42

1. Spring Washers

3. Dust Cap

2. Lock Nut

Cooling System

Maintenance

Cleaning the Air Intake

Screen

Before each use remove any build-up of grass, dirt

or other debris from the cylinder and cylinder head

cooling fins, air intake screen on flywheel end, and

carburetor-governor levers and linkage. This will

help insure adequate cooling and correct engine

speed and will reduce the possibility of overheating

and mechanical damage to the engine.

Cleaning the Cooling System

Clean the air intake screen from grass and debris

before each use.

Check and clean cooling fins and engine shrouds

every 100 hours or yearly, which ever comes first.

1. Disengage the PTO and set the parking brake.

2. Stop the engine, remove the key, and wait for

all moving parts to stop before leaving the

operating position.

3. Remove the guard, air intake screen and fan

housing (Figure 43).

37

Summary of Contents for Z334 Z-Master

Page 8: ...Slope Chart 8 ...

Page 44: ...Figure 53 1 Keep the end of the bolt ush with the nut 3 Nut 2 Rear pivot bracket 4 Bolt 44 ...

Page 54: ......

Page 55: ......